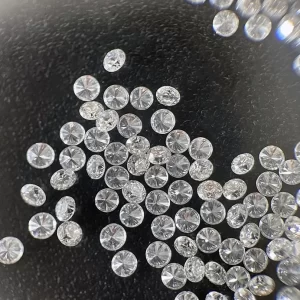

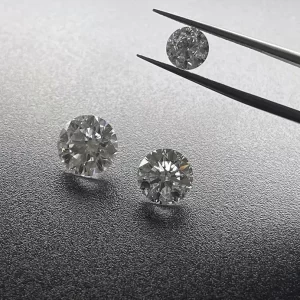

Yellow Color 3.6mm Low Purity HPHT Mono Crystal

Yellow Color 3.6mm Low Purity Hpht Mono Crystal For Industrial Diamond Tools

Hpht Mono Crystal Description

Lab diamonds are real diamonds. Carbon is the main element of natural and laboratory-grown diamonds. The chemical and physical properties of synthetic diamonds are same as natural diamonds in terms of hardness, thermal conductivity, and strength.

High temperature and high pressure (HPHT) and chemical vapor deposition (CVD) are the two most commonly used growth methods in synthetic diamonds industrial. High temperature and high pressure exert intense heat (about 1500 degrees Celsius, or 2700 degrees Fahrenheit) and pressure (1.5 million pounds per square inch) on the diamond seed and the carbon atoms surrounding it. Chemical vapor deposition, on the other hand, uses less heat and pressure, but introduces a mixture of chemical gases, which decomposes and hardens into crystalline carbon atoms.

Pure diamond is the best insulator, and diamond doped with impurities (such as type Ⅱ B diamond) is an electron like or hole like semiconductor. This kind of semiconductor crystal can withstand 1000 ℃ corrosive medium (such as alkali and acid) and high dose radiation. Diamond can be used in machine manufacturing, laser technology, electronics, acoustics, chemistry and medicine. Diamond chips are mainly used in integrated circuits and cold cathode electron tubes, which is conducive to greatly reducing the size of the equipment and improving the computing speed of the computer.

Diamond Size: 3.6mm

Application: Diamond tools making

Low Purity HPHT Mono Crystal and High Purity CVD Diamonds

If you are looking for a diamond substitute, consider High-purity CVD diamonds. These diamond substitutes have high-purity properties, while synthetic single-crystal diamonds have inclusions. Read on to learn more about these synthetic diamonds. Listed below are some of the differences between natural diamonds and synthetic diamonds. You’ll also learn how these diamond substitutes are made and why they are useful.

High-purity CVD diamonds

The process for growing diamonds in a laboratory begins with a low-purity HPHT mono crystal. The sample is then heated and pressure loaded to produce diamonds. The temperature is lower than the melting point of pure metals, such as metallic Ti. In contrast, the eutectic temperature of HPHT diamonds is lower than the carbide barrier. The result is a high-purity CVD diamond that is uncoloured.

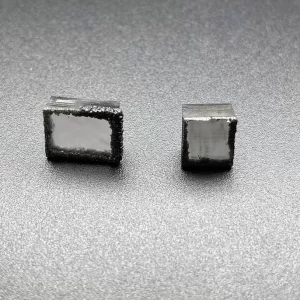

When compared with a low-purity HPHT mono crystal, the optical properties of a high-purity CVD diamond are very similar. This material displays no visible layers and a high-intensity ratio, making it a promising material for high-pressure optical windows. However, the presence of a nitrogen leak can lead to a color difference in the high-purity CVD diamond. Inclusions are another feature that can help distinguish between low-purity and high-purity CVD diamonds.

When the growth temperature reaches a higher value, nitrogen atoms in the diamond structure aggregate into pairs. In other words, higher partial pressure of nitrogen increases the solubility of nitrogen in Fe. This process is called diamond synthesis. For the same reason, diamonds produced from HPHT mono crystal are also nitrogen-poor. This is not to say that natural diamonds are nitrogen-poor, as they are often surrounded by sulfonated compounds.

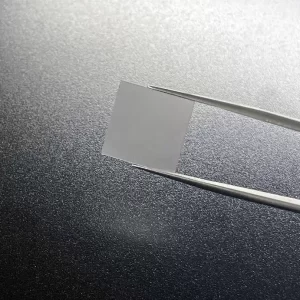

The process for creating HPHT synthetics is similar to that for making polycrystalline diamonds, but in this case, the growth takes place inside a vacuum chamber. The growth chamber is filled with hydrogen-carbon gas, and the microwave beam breaks apart the molecules and carbon atoms diffuse toward the colder seed plates. After weeks, the crystals will start to grow, and the amount of crystals produced depends on the size and number of seed plates used in the process. Typically, the resulting crystals are tabular and blue in color, but other colors can be obtained by post-growth processes.

The process can be refined to produce single crystal CVD diamond anvils with high growth rates and no annealing. One example is a 2.3-carat colorless round CVD diamond fabricated at a growth rate of 50 mm/h. During this process, there are no impurities in the diamond and the material is thus of superior optical quality.

Single-crystal CVD diamonds have many advantages over polycrystalline diamonds. In contrast, higher-growth rate processes produce polycrystalline diamonds. Several methods have been devised for the growth of single-crystal diamonds. One method adds nitrogen to the MPCVD reaction chemistry, which improves facets growth and produces diamonds with smooth surfaces. In this study, Yan et al.1 reported growth rates of 100 mm/hr.

GC-MS analysis of diamond melts revealed a complex composition of volatiles trapped within the diamond crystals. The major component of these volatiles is a group of aliphatic hydrocarbons, which contains 47 rel% in paraffins and 18 rel% in olefins. Moreover, nitrogen is low in diamonds from the Fe-Ni-C system, with structural nitrogen levels of 105-108 ppm. However, the composition of volatiles changed when metallic Ti was introduced. The amount of oxygenated hydrocarbons increased to 43 rel%.

Synthetic single crystal diamonds

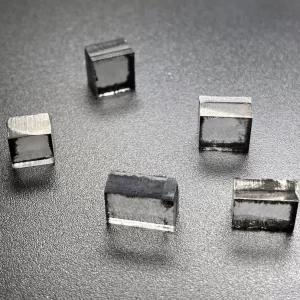

HPHT mono crystal diamonds are produced using high pressure high temperature synthesis under carefully controlled conditions. The growth conditions used to produce these diamonds are extremely precise, making them ideal for producing high-quality gems. HPHT diamonds come in a variety of shapes, including round, triangular, and sex-angle. They can be faceted into various shapes to meet the needs of a variety of jewelry makers.

The initial raw material used in the development of these synthetic diamonds is a high-crystalline synthetic micron diamond powder consisting of 80-100 mesh cubooctahedral diamond crystals. The initial raw material is nitrogen jet milled to produce 97% of the particles below 2 mm in size. An aliquot of this powder is ball milled under argon to produce NDs (non-cubic-cubic-hedral diamonds). The resulting single crystals have a crystalline structure with a quasi-spherical shape and an aspect ratio of 1.13 to 1.75.

The first step in the production of synthetic diamonds is to prepare the substrate and then feed the varying gas mixtures into the chamber. Depending on the chemical composition of the substrate, Ni and Co are commonly added to reduce the melting point of the Fe. The process requires that the substrate be cleaned and abraded, in order to remove any non-diamond materials. The nitrogen in these diamonds is trapped within the growing crystal and is responsible for the yellow color of the finished product. Nitrogen is produced during the process by dissociating in transition metals of the Fe group. This nitrogen is sourced from air.

High pressure high temperature synthesis is an excellent way to produce large-sized diamonds. HPHT produces both type II and low-birefringence diamonds and has an excellent crystalline perfectivity. The HPHT sample contained less than one ppb of boron and nitrogen impurity atoms in the growth sector. The sample also exhibits decoration of the growth sector interface. Moreover, negatively charged nitrogen vacancy centers are used to calculate the relative growth rates.

High-purity synthetic HPHT single-crystal diamonds are being produced by New Diamond Technology (NDT). These SCD plates possess a high growth rate and are of excellent quality. The MCT single crystals have an average growth rate of 50-150 mm per year and a low level of uncontrolled impurities. They are available in various sizes and can also be custom-made.

During HPHT diamond growth, the carbon starting material is enclosed in a small capsule. It is surrounded by an apparatus capable of producing high pressures. The carbon starts material migrates through the flux towards a diamond seed at a lower temperature. Crystallization occurs over days to weeks. There are a few important factors that affect the rate of crystallization in HPHT diamonds. However, the emergence of a single crystal is a complicated process that is not without challenges.

Inclusions in synthetic diamonds

Inclusions in synthetic diamonds are found in the crystals of the Fe-Ni-Ti-C system. These metals are incorporated into diamond crystals by a process called melt inclusion. The element maps of synthetic diamonds obtained with the BSE technique and the element maps of magnetic and x-ray diffraction show that these inclusions are formed as a result of the melting process.

Natural diamonds contain metallic inclusions but these are much rarer than those found in synthetic diamonds. These diamonds exhibit self-purification during the post-crystallization heating. The magnetic properties of synthetic diamonds help researchers identify these inclusions. These inclusions are largely invisible to the naked eye. However, they can be picked up with a magnet. Inclusions in synthetic diamonds are often present and may be present, depending on the crystallization conditions in the kimberlite.

These inclusions do not affect the performance of a diamond, but they can affect its beauty. The size of the inclusion, its location in the stone, and the number of inclusions will influence the clarity grade. Precise identification of the hydrocarbons has been difficult until the invention of the GC-MS technique. However, it is now possible to perform detailed identification of these inclusions. Inclusions in synthetic diamonds may also cause a decrease in the durability of the stone.

Inclusions in synthetic diamonds may also be controlled with the use of a portable measuring instrument called DiaSusz. Magnetic inclusions in synthetic diamonds can be manipulated using DiaSusz. The magnetic susceptibility of synthetic diamonds is caused by residuals of a magnetic catalyst in the crystal. The use of this method provides a fast indirect method of identifying metal content in synthetic diamonds. If you are looking for a high-quality diamond, then DiaSusz could be the tool you need.

Inclusions in synthetic diamonds can occur due to various processes. The process for creating synthetic diamonds involves a high-pressure annealing method. The supercritical fluid increases the proportion of complex hydrocarbons, including nitrogen, in the diamond. During the process, the nitrogen atoms are bound to the C-centers, preventing dissociated nitrogen from entering the diamond’s structure. Inclusions may also be formed due to thermal interactions, such as those that result in the formation of A,B, and C-centers.

While the infrared absorption of samples demonstrates that some CVD diamonds have a low color grade, the color of CVD diamonds in their as-grown state is brown. This color is often caused by nitrogen elements, and the brown diamonds are treated under HPHT, a process that renders them near-colorless or colorless. As a result, the infrared spectra of CVD diamonds reveals a higher level of abnormal birefringence than the natural diamonds.

While the diamonds in nature are highly rare and expensive, they do contain a variety of different types of solid phases. In synthetic diamonds, these inclusions occur in a variety of shapes. During the growth process, the elements of the synthetic diamonds can be added, including Ti and Zr. Mg and Zr are both strong reducing agents and can help form diamonds. They also have similar chemical properties to diamond.

Yellow Color 3.6mm Low Purity HPHT Mono Crystal