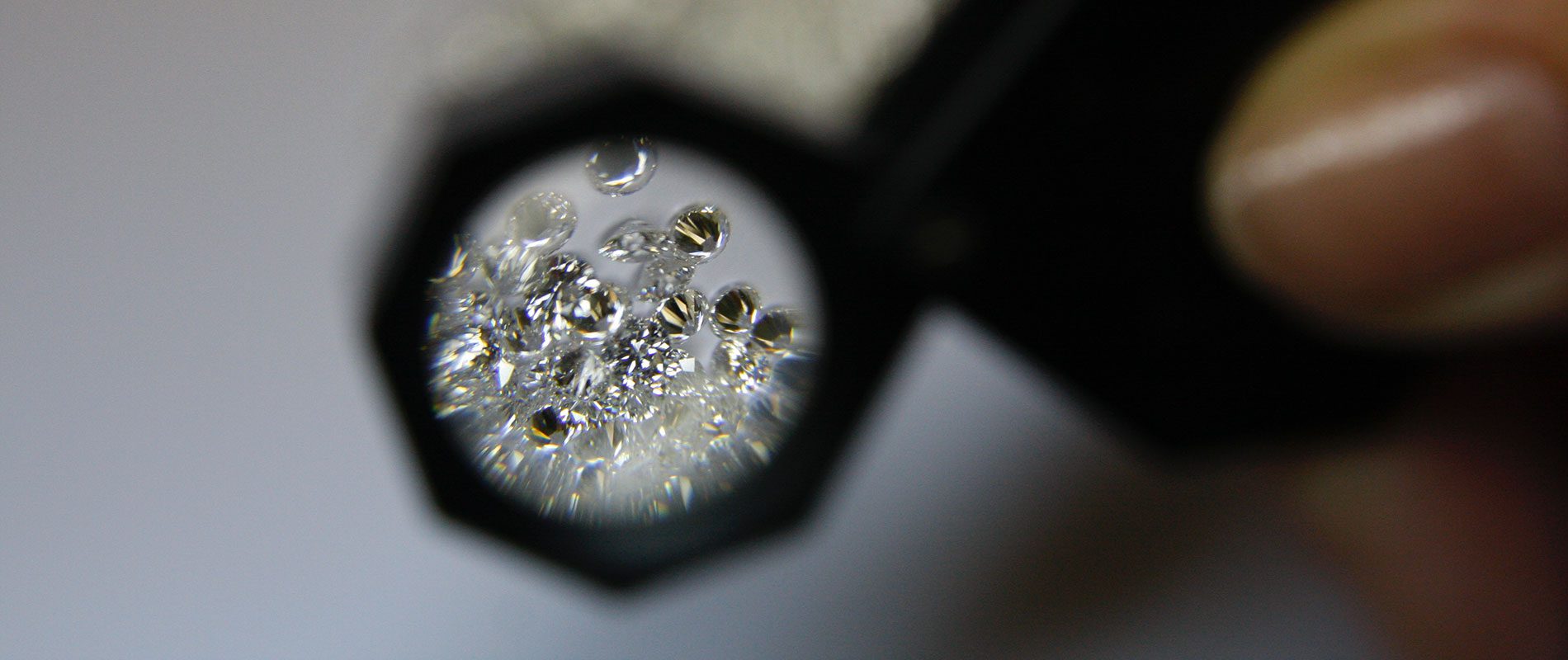

Mining Free

“NO MINING” is required for Lab created diamonds. Elevate your jewelry with mining free Lab Growm Diamonds

Quality

The physical, chemical, and optical properties of lab-grown diamonds are identical to those of naturally occurring diamonds.

Valuation

Lab made diamonds contribute excellent value,

and are more affordable than natural diamonds

about us

Lab grown diamonds are absolutely identical to mine diamonds except their origin.

To fulfill the increasing demand for lab-grown diamonds, our company is one of the world’s leading suppliers. We offer high quality rough(including HPHT and CVD), polishable faceted gemstones as well as industrial grade material at competitive prices to both wholesale clients or those looking just buy directly from us!

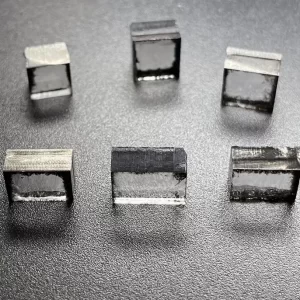

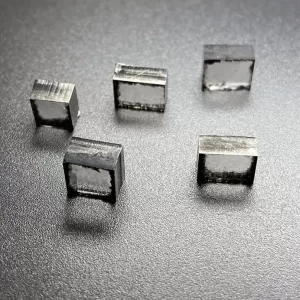

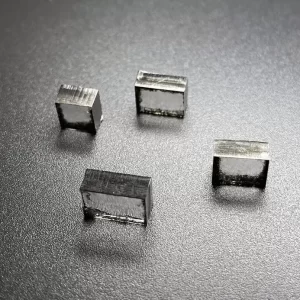

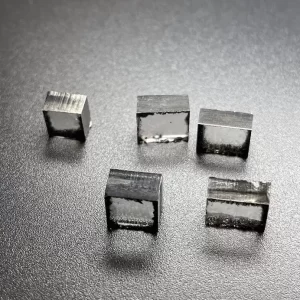

OUR PRODUCTS

We render an extensive range of internationally graded man-made diamonds you would fall in love with.

- All Products

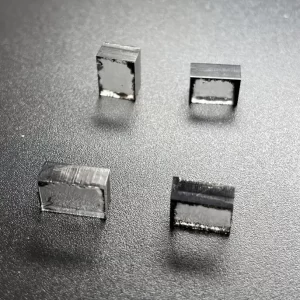

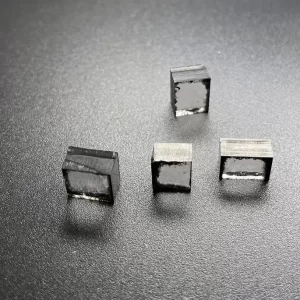

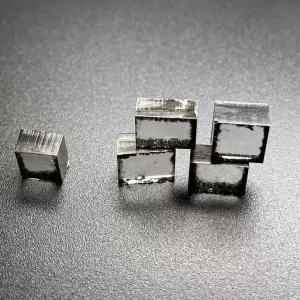

- CVD Rough Diamonds

- All Products

- CVD Rough Diamonds

Our Products Applications

Due to production know-how, we have an opportunity to grow the purest type IIa diamond plates of large sizes without any losses of unique properties of a diamond, which create new opportunities for optics production.

Crystal-clear diamond plates up to ½ inch sizes, retaining their extreme hardness and high coefficient of thermal conductivity have a high demand in medical, military, aerospace and research industries; they are highly used in particle acceleration process, laser systems, analytical instruments and other high-power equipment.

Our diamond components can be used as UV and IR windows, laser optics components, lenses for gyrotrons, monochromators and X-ray focusing equipment, particle detectors and even to increase the quality of information transmission. Due to it’s high refractive index an optical diamond element can minimize information losses during transmission of a signal with the highest safety level in addition to the capacity increase.

We produces the purest colorless type IIa diamonds, but for micro and power electronics we are able to add the necessary concentration of boron in the synthesis process to obtain better material conductivity (types IIb and IIa+IIb) used in electro-chemical industries.

Achieved results in collaboration with European partners have shown that chemical stability, conductivity and thermal shock resistance of diamonds differ them from other materials and creates a high demand in many electro-chemical sectors of industry as a semiconductor component, key element in diodes, transistors and thyristors, electrode in electrolytes, sensors, integral component in medical and UHF equipment.

Radiation detectors and monitors

A single-crystal diamond with low dislocations level grown by Us has a large effective surface (up to 90% of the total) and high sensitivity of the surface, which makes it a perspective material for particle detection in the radiation environment. Compared to currently used silicon (Si) based sensors, diamond sensors are able to detect much more signals, are the best electrical insulator and wear-resistant material. The use of a diamond in this sphere is now widely recognized by high-energy particle detectors community all around the world.

Quantum applications

The ideal atomic structure of our diamonds is perfect for research in the sphere of quantum photonics and optics. The spin of the electron in the Hydray center (an atomic level defect in a diamond) was proved to be effective media storage for information and quantum computing. Type IIa diamonds with low-dislocation level and without impurities and contaminations are one of the most perspective solutions in this sphere. Although this technology is still in at a development stage, there is no doubt that such material as diamond will play very important part in quantum research.

Thermal applications

A diamond by far surpasses its main competitors: silicon (Si), silicon-carbide (SiC) and gallium-nitride (GaN) in thermal conductivity. Thermal conductivity of diamond plates is ranging from 1000 to 2000 W/mK, however, due to unique technology our single-crystal subs have shown better results averaging approx. 2100 W/mK.

Our diamond is able to fully remove the heat or to change temperature of high-power sources in order to prevent overheating, damage and destruction of the working module. Diamond heat sink substrates allow to increase capacity of the operating modules and their life time in extreme conditions. It is very important for semiconductor industry, in wich currently it is not possible to develop UHP and fast processors and it stays only a dream of a technologist at this stage and time.

Mechanical applications

Diamond is known for its unique hardness. Strong and tough carbon compounds formed billions of tetrahedral cells which are the source of mechanical strength of diamonds. Perfect, clean diamonds of (111) and (100) have the highest level of rigidity and hardness and are ideal for high-precision mechanical engineering applications.

The ideal crystal purity guarantees high wear resistance and low coefficient of tool friction even if a diamond layer is very thin. Strong diamond material significantly increases life-time of an instrument and equipment, providing more cost-effective solution in long-term perspective.

HPHT diamond plates are ideal substrates for deposition additional layers using CVD method. Moreover, We plates open new horizons for researchers and scientists because of its unique large sizes, low-level of dislocations and other important characteristics.