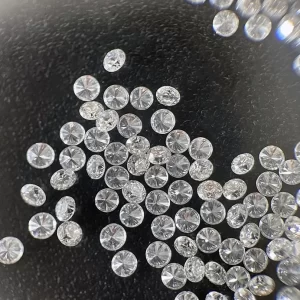

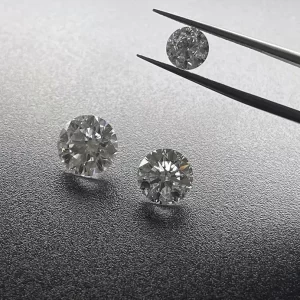

Yellow 3.2mm Mono Synthetic HPHT Industrial Diamonds

Yellow 3.2mm Mono Synthetic HPHT Industrial Diamonds For Making Diamond Dresser

Synthetic HPHT Industrial Diamonds Description

Lab diamonds are real diamonds. Carbon is the main element of natural and laboratory-grown diamonds. The chemical and physical properties of synthetic diamonds are same as natural diamonds in terms of hardness, thermal conductivity, and strength.

High temperature and high pressure (HPHT) and chemical vapor deposition (CVD) are the two most commonly used growth methods in synthetic diamonds industrial. High temperature and high pressure exert intense heat (about 1500 degrees Celsius, or 2700 degrees Fahrenheit) and pressure (1.5 million pounds per square inch) on the diamond seed and the carbon atoms surrounding it. Chemical vapor deposition, on the other hand, uses less heat and pressure, but introduces a mixture of chemical gases, which decomposes and hardens into crystalline carbon atoms.

Diamond is a kind of mineral composed of carbon element, which is allotropic body of carbon element. Diamond is the hardest material in nature. Diamond has a wide range of uses, such as: Arts and crafts, industrial cutting tools. Graphite can form synthetic diamond at high temperature and high pressure.

Diamond is a non-metallic mineral composed of natural element carbon (c). Except diamond, other transparent gemstones are minerals composed of many elements.

The hardness of diamond in 10 representative minerals of “Mohr hardness” is 10, which is the hardest. And in the “absolute hardness” measured in the “NOP” value (unit: kg / mm), diamond is 8000, corundum 2000, quartz (or crystal) 1000, diamond is also the hardest, so it is the hardest solid material in nature.

Diamond Size: 3.2mm

Mesh Size: 8/10 plus

Mono Synthetic HPHT Industrial Diamonds

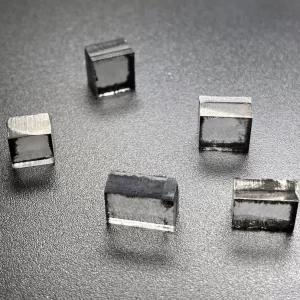

If you’re looking for abrasive materials that are both durable and cost-effective, you’ve probably heard of polycristalline diamond tool blanks. These blanks are a mixture of cobalt and diamond micron-powder with a high thermal conductivity. Compared to natural diamonds, they have more than five times the abrasive capacity. Diamonds made through the HPHT process also have a flat top and plate-like crystals.

Synthetic diamonds are made in a lab

Natural diamonds grow through intense heat and pressure over millions of years. In contrast, synthetic diamonds grow over a period of weeks. They begin as a tiny diamond seed that is coated with a material that mimics the conditions in the Earth’s crust. This coating eventually turns the diamond seed into a synthetic diamond. Because synthetic diamonds are made in a lab, they have the same chemical properties as natural diamonds.

During the 20th century, researchers were making attempts to produce synthetic diamonds. Many claims were published between 1879 and 1928, but the results were not confirmed. Only in the 1940s, Sweden and the United States did scientists begin systematic research into the process of diamond creation. This research eventually led to the first reproducible synthesis in 1953. Diamonds produced using this method are referred to as HPHT diamonds, or high-pressure, high-temperature, and CVD diamonds.

Natural diamonds are formed millions or billions of years ago. The processes used to create synthetic diamonds are based on the process of growing carbon under high temperature and pressure. As a result, lab grown diamonds exhibit the same properties and characteristics of natural diamonds, but without the inherent flaws that make natural diamonds so special. Although the synthetic diamonds are produced in laboratories, the process does require an advanced lab.

Despite the high costs of natural diamond mining, the environmental and human costs associated with mining diamonds are significantly reduced with the creation of lab-grown diamonds. Since lab-grown diamonds have virtually the same physical properties as natural diamonds, synthetic diamonds are a great alternative to traditional diamonds. In fact, De Beers recently launched its own lab-grown diamond line, Lightbox. The combination of lower prices, increased accessibility, and ethical sourcing make synthetic diamonds an ideal choice for many buyers.

They are cheaper than natural diamonds

The HPHT process creates diamonds with a perfect structure and a minimal amount of uncontrolled impurities. HPHT industrial diamonds are cheaper than natural diamonds and are remarkably consistent in quality. The manufacturing process utilizes a unique method to control diamond crystal morphology. The results are diamonds that are transparent, hard, and can range from 8 mm to 7 carats in size. These diamonds are also 30% cheaper than the average market price.

In the 1950s, scientists synthesized the first diamonds and now almost all industrial diamonds are produced synthetically. They are used primarily in abrasive cutting tools. Through continuous innovation, synthetic diamonds have advanced in size, clarity, and purity. The potential for growth of near-perfect diamond crystals is virtually unlimited. As a result, synthetic diamonds are far cheaper than natural diamonds.

Another factor in the cost of lab-grown diamonds is their smaller size. Natural diamonds are far more expensive than lab-grown diamonds. The lab-grown variety, on the other hand, is significantly cheaper than natural diamonds. In some cases, lab-grown diamonds can be up to 60% cheaper than natural diamonds. The cost difference varies depending on the quality and size of the stone.

A good way to determine if HPHT Industrial Diamonds are artificial is to analyze the fluorescence of the stones. The fluorescence of natural diamonds varies with their composition and can only be detected by using an instrument called DiamondView. The instrument uses different excitation wavelengths, enabling the manufacturer to distinguish natural diamonds from synthetic diamonds. When comparing natural diamonds and HPHT diamonds, remember that the artificial ones are often cheaper and of better quality than their natural counterparts.

They are used as abrasives

There are numerous advantages of using high pressure high temperature (HPHT) industrial diamond for abrasive applications. Its unique properties include high thermal conductivity, low thermal expansion, chemical inertness, optical transparency, and resistance to chemical corrosion. New developments in the field of diamond synthesis have enabled researchers to exploit the full potential of this natural stone. Today, HPHT diamond is preferred for abrasive applications due to its properties.

The process of synthesis involves a number of steps. First, the process must follow the phase diagram of carbon. Once the diamond phase is formed, it requires high temperatures and high pressures. Diamonds are manufactured in industrial facilities using specially designed anvils. In this process, carbon atoms are covalently bonded with four other carbon atoms, creating a crystal lattice with two atoms per unit cell.

Another process of manufacturing monocrystalline diamonds is HPHT technology. This method produces a near-colorless stone. However, its price tag is much lower than natural diamond. It is also available in very large sizes of up to 10 carats. Developed in China, the HPHT industry developed quickly. Today, China has become the largest supplier of HPHT diamonds and has an excellent manufacturing industry.

Because synthetic diamonds are artificial, they do not require the constant rotation of tool wheels. They are longer than natural diamonds, and they maintain their condition even after being cut and polished. They are thus highly efficient for many industrial applications. However, these diamonds are still not considered as “natural” and are not recommended for use in industries that require extreme performance. Therefore, they are not considered to be the best alternative for all applications.

They have no fluorescence

Most high-quality diamond parcels have lower synthetic percentages, and in some cases, they are fluorescence-free. However, the synthetic percentage does not reflect other qualities or market trends. For example, Indian diamonds have a significantly higher synthetic percentage than diamonds from other countries. In addition, these diamonds are difficult to distinguish from natural diamonds, which show some fluorescence, because they are synthetically made.

High-pressure, high-temperature (HPHT) synthesis of diamonds is a standard industrial technique for growing diamonds with a wide range of lattice parameters. Modern high-pressure processes employ non-conventional metal catalysts, which enable the use of nitrogen-containing additives, metal getters, and low nitrogen content. In addition, HPHT processes are commonly used to anneal diamond crystals and decolour them, as well as to sinter them into larger polycrystals.

Optical spectroscopy (FTIR) is one way to detect natural diamonds by their fluorescence. Diamonds naturally display a bright, mosaic, or banded pattern of fluorescence. These interference colors are the result of diamond stress. Conversely, HPHT diamonds do not have any strain pattern and show only a weak banding. Furthermore, these diamonds exhibit unusual fluorescence. Natural diamonds show the strongest fluorescence under long-wave UV, while HPHT synthetics exhibit a weak banding pattern in the IR.

Some diamonds exhibit blue nuance. This coloration is often the result of excess boron. It is not uncommon for HPHT-grown diamonds to have visible amounts of boron. However, it is difficult to remove this element during the growth process, making it costly to produce diamonds with no fluorescence. Moreover, the less boron a diamond has, the more valuable it is.

They are made of pure carbon

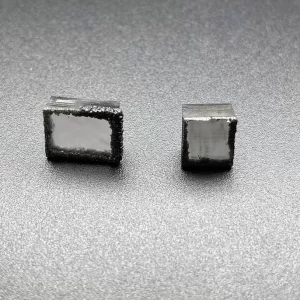

HPHT treatments of mono-synthetic diamonds result in the creation of zones containing N3 centers (415.9 nm), which are combined with H3 centers (503.1 nm) to form a colorless, crystalline structure. This makes HPHT diamonds appear sectored. Compared to their HPHT cousins, mono-synthetic diamonds are made of pure carbon.

The X-rays that detect diamond grits reveal a yellow fluorescence. Since then, the De Beers Diamond Research Laboratory has been able to grow stones up to 11 carats in weight, although most are around one to 1.5 carats for economic reasons. The introduction of the Russian BARS apparatus into the diamond industry has also affected its quality. However, the high-quality stones made in the US are often free of synthetics.

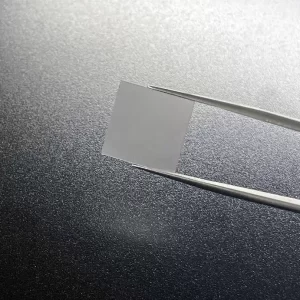

The manufacturing process for industrial diamonds starts with the preparation of a diamond substrate. Then, various gases, including hydrogen and methane, are fed into the machine chamber. Microwave power is used to activate radicals in the growth chamber. Once this step is complete, an expert will polish the diamond to the standards that natural diamonds would have. Moreover, the quality of mono-synthetic diamonds is equivalent to that of natural diamonds.

HPHT is a method used to grow diamonds in laboratories. It simulates conditions in the earth’s crust and allows the growth of diamonds in a lab. To create a mono-synthetic diamond, carbon atoms are subjected to extremely high temperatures and pressures. The carbon atoms then bond with each other to form the diamond atom by atom. The process takes several days or weeks and results in a single-sided, crystalline diamond.

Yellow 3.2mm Mono Synthetic HPHT Industrial Diamonds