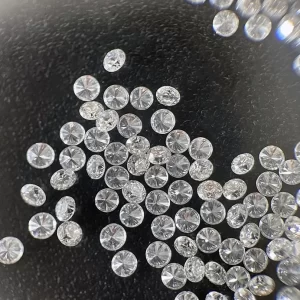

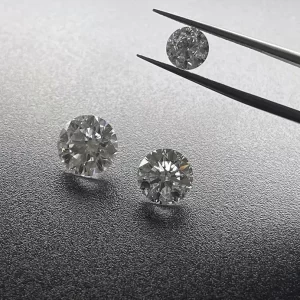

DEF White Color VS SI Clarity 8.0 Carat To 10.0 Carat HPHT Raw Diamond Stone For Diamond Rings

Lab Grown Rough Diamonds Description

What are the diamonds produced in the laboratory?

These stones are not created by the power of nature as they were millions of years ago, but by works of art in which one can participate. The diamonds were produced in industrial laboratories under the guidance of talented chemists, gemologists and technologists. Their creation process is close to nature, but much faster.

Since the best method of making stone was invented in the 1970s, the stone cultivated in the laboratory has been actively used. They are used in precision engineering, electronics and, of course, beauty and fashion. It is in the case of jewelry production that the diamonds cultivated in the laboratory are really shocking. He gradually removed the natural gems from the base, because the difference was invisible to the inexperienced.

What is the name of a diamond made in a laboratory?

Here are some names of diamonds that are grown in the lab. Depending on the manufacturer, it may be called mosangite (like rare gems extracted from meteorites), a silica (if it was produced by fian, a Russian laboratory that developed the stone formula), and even Swarovski crystals, which are popular. But it is important to note that the closest diamonds to nature are only mozang stones, which are recognized as the best diamonds to grow in the laboratory.

How diamonds are made in the laboratory

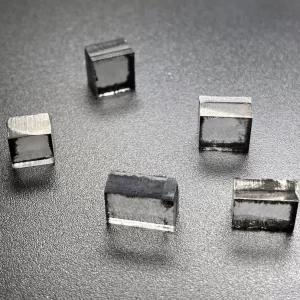

High temperature and high pressure are two main rules for diamond acquisition. Naturally, they are carbon that is deeply pressed in the crust at high temperatures. After human beings have learned about the structure of a real diamond, we have tried to repeat it manually. Today, there are two main manufacturing methods. The first is high temperature and high pressure, the second is chemical vapor deposition. The two methods are both interrelated and complementary.

HPHT DEF White Raw Diamond

You’ve probably heard of HPHT, High pressure high temperature, and Chemical Vapor Deposition (CVD), but have you heard of HPHT DEF White Raw Diamond? Before you buy, here are some things to know. HPHT DEF is only used on high-clarity diamonds. It will not work on diamonds with fractures or inclusions. GE Diamond is another example. So, what’s the difference between a diamond that’s been treated by HPHT and a natural diamond?

High pressure high temperature method

The HPHT DEF white raw diamond method can transform a yellow diamond to a near-colorless stone. This treatment is a permanent one, and the change in color doesn’t affect the original color of the diamond. Unlike mined diamonds, lab grown diamonds do not put as much stress on the environment. They do not require mining of minerals, and the average consumer can’t tell the difference between a natural and a lab-grown diamond. Before you buy a diamond, be sure to read the certificate and get a certificate from a reputable lab. The lab’s certification will indicate whether a diamond was HPHT treated or not.

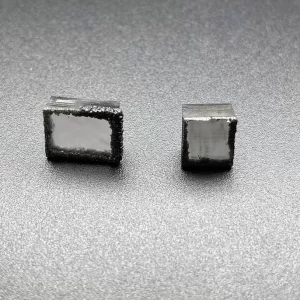

The difference between a natural and a lab-grown diamond is even greater when the stone weighs more than a carat. A 3 carat natural diamond costs $32,930 compared to a $15,750 lab-grown diamond – a difference of more than 50%! This method was developed by the Gemological Institute of America to distinguish between natural and lab-grown diamonds. These synthetic diamonds are produced by a high-pressure, high-temperature process, which is also used in laser optics and telecommunications.

This process is faster than the previous one, and can produce a beautiful, durable diamond without the risk of chemical reactions. It can even make diamonds of unmatched whiteness! While natural diamonds take millions of years to form, the HPHT DEF white raw diamond method can create a beautiful diamond in just a few hours. Using a molten metal, high pressure and temperature conditions replicate the conditions of diamond-forming volcanoes in the earth. A small diamond seed crystal is placed in this solution. Then, under the right conditions, the carbon atoms will precipitate onto a small diamond seed crystal. Once the diamond is ready, a diamond cutter will cut the lab-grown diamond into an attractive, polished, and durable stone.

Another type of HPHT diamond is called an “as-grown” diamond. HPHT diamonds are more difficult to grow and more expensive, but the process is faster and more consistent than the CVD method. CVD diamonds are inferior in quality and typically have a brown or grey color, but the color is enhanced using a post-growth treatment. Hence, the HPHT process is preferred by many because it is faster.

Chemical vapor deposition

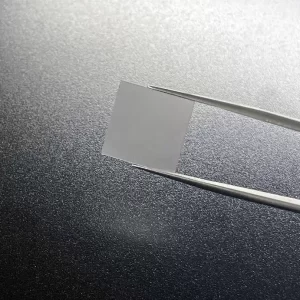

The process of CVD, or chemical vapor deposition, creates a diamond by putting a gas called diborane or nitrogen into a vacuum chamber and applying pressure. This gas then forms diamond crystals, and the resulting samples are characterized by their high purity and crystalline orientation. The CVD process results in diamonds with different crystalline orientations, and the nitrogen present in the gas increases its growth rate and produces a white raw diamond.

The patent also focuses on achieving gem-grade diamonds from white raw diamond. In the process of CVD diamond synthesis, small amounts of dopants are added to the diamond crystal, which then improves its clarity and color. This is accomplished by compensating the nitrogen and Boron centers of the diamond mono-crystals. Once the diamonds have been created, the process involves heating them at high temperatures to achieve the desired crystallinity and color.

Diamond electrodes can be reactivated by polishing. This procedure does not pose any risk to the electrode surface. This property is especially important for bulk oxidation of contaminants in solution. Most electrochemistry is carried out in aqueous solution, where water is electrolysed into hydrogen gas at the negatively charged cathode and oxygen gas at the positively charged anode. The resulting diamond electrodes are extremely versatile and are used in a variety of applications, from jewelry to semiconductor applications.

CVD is a relatively inexpensive way to create a white diamond. It relies on a unique process and a high temperature to grow a diamond seed. The gas must contain hydrogen, which is necessary for CVD. Once the gas is activated, the hydrogen breaks apart the double bonds in graphite and converts them into diamond bonds. The growth rate of a CVD diamond is slow, between 0.1 microns and 100 microns per hour.

CVD diamonds are the closest imitations of natural diamonds, with the same physical properties. However, because they are not formed within the Earth, the two types cannot be distinguished even by trained jewelers. In 2018, the Federal Trade Commission (FTC) ruled that a natural diamond and a synthetic diamond are equal. But is it possible to tell the difference between the two? This article will reveal how to distinguish a natural diamond from a CVD diamond.

GE Diamond

This article is not an advertisement for GE Diamond, but rather a fact sheet to help you understand the difference between HPHT synthetic and natural diamonds. Both types of diamonds are created the same way, but one has an advantage over the other. A HPHT diamond is a natural diamond, whereas a non-HPHT diamond has been treated to add color and make it look like a real diamond.

HPHT synthetics are manufactured using the same processes as natural diamonds, but often contain ash-like or rod-like metallic inclusions. The process also results in a high-energy and short-wavelength UV source, which produces fluorescence reactions. The inclusions within the diamond can become unstable and explode if the temperature is too high. However, most HPHT synthetics will not show any reaction to a standard long-wave UV light source.

HPHT is the most common method for creating a lab diamond. The process replicates the conditions that natural diamonds undergo, including extreme heat and pressure. In fact, Hall was the first to produce a CVD diamond, but his creations weren’t gem quality. Hall and his team struggled to create diamonds without inclusions, and eventually found an improved method, known as tetrahedral press.

Colorless diamonds that have an FTIR spectrum that shows no nitrogen are type II. Type Ia diamonds have an IR absorption spectrum that reflects their average concentration across the bulk of the diamond. However, if a diamond doesn’t have this inscription, it is likely a synthetic and should be avoided. The girdle of a diamond containing a trace amount of HPHT synthetic material is also useful in identifying the type of diamond it is.

GE Diamond HPHT DEF White Raw – A lab diamond can be either white or yellow, or any colour you choose. Both of these options are cultivated diamonds. The difference between natural and lab diamonds is the source of carbon. The HPHT method is cultivated from carbon, which is obtained from methane. At temperatures of eight hundred to one thousand degrees Celsius, carbon atoms deposit on a diamond seed, while the CVD process uses methane as a carbon source. The growth rate for pure carbon structures is slow, but can be accelerated with nitrogen. A 10ct crystal is possible in as little as three to four weeks.

Natural diamonds

The Gemological Institute of America, or GIA, developed an instrument that identifies natural diamonds from HPHT enhanced stones. Although these enhanced stones do look very similar to naturally-mined diamonds, they are not interchangeable. Because HPHT treatments are not always transparent, consumers may be unable to tell a real diamond from an HPHT enhanced one. Because of this, it is essential to ask the seller to provide a diamond certificate for the HPHT treated ones.

Natural diamonds were formed billions of years ago under great pressure and heat. These diamonds traveled up to the earth’s surface in volcanic pipes. They are three times deeper than an average volcano. This is one of the reasons they are so expensive. Compared to the natural diamonds, HPHT-treated diamonds are relatively affordable. They also don’t involve the conflict and destructive mining that occurs during diamond mining.

While lab-created diamonds are far less expensive than natural diamonds, their resale value has decreased considerably. Buying a lab-created diamond will likely cost you approximately half the price you paid for a natural diamond. The price of lab-created diamonds also varies wildly from one retailer to another. Nevertheless, both diamond types are valuable and have their own unique characteristics.

A small diamond seed is placed inside a chamber of carbon. The carbon is heated to a temperature of over 2,000 degrees Fahrenheit. At this pressure, the carbon melts, creating a diamond around the seed. The entire process can take a couple of days or weeks to complete. Finally, the diamond seed is extracted, cleaned and polished. Once it has been processed to the desired quality, it can be sold.

HPHT is an industrial process that uses high temperatures and pressure to improve the color of diamonds. It can enhance a diamond’s color by anywhere from four to six levels. However, not every diamond is suitable for HPHT. In order to be eligible for this process, it must be J color and have a high-clarity value. HPHT treatment may also change the color of the diamond, so it’s important to find out whether you can afford an HPHT treated diamond.

VS SI HPHT DEF White Raw Diamond 8 Carat 9 Carat 10 Carat