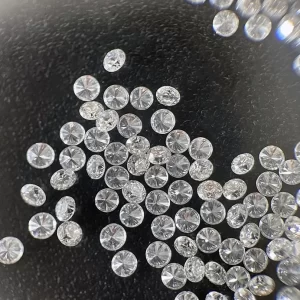

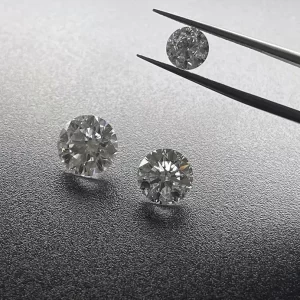

1.0mm To 4.0mm HPHT Monocrystalline Diamonds Yellow High Pressure High Temperature

The HPHT monocrystalline diamond is produced by combining a mixture of carbon and transitional metals at very high pressures and temperatures.

Crystal Structure: Single crystal

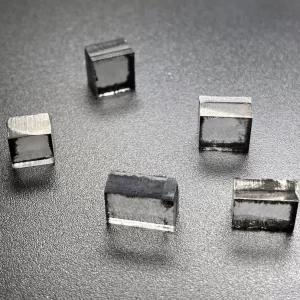

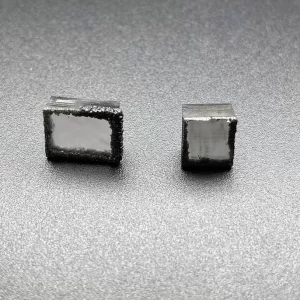

Application: diamond cutting and sharpening tools

Color: Yellow

Hpht Single Crystal Diamonds Description

Lab diamonds are real diamonds. Carbon is the main element of natural and laboratory-grown diamonds. The chemical and physical properties of synthetic diamonds are same as natural diamonds in terms of hardness, thermal conductivity, and strength.

High temperature and high pressure (HPHT) and chemical vapor deposition (CVD) are the two most commonly used growth methods in synthetic diamonds industrial. High temperature and high pressure exert intense heat (about 1500 degrees Celsius, or 2700 degrees Fahrenheit) and pressure (1.5 million pounds per square inch) on the diamond seed and the carbon atoms surrounding it. Chemical vapor deposition, on the other hand, uses less heat and pressure, but introduces a mixture of chemical gases, which decomposes and hardens into crystalline carbon atoms.

Diamond has always been favored by the scientific and industrial circles, and is widely used in optics, semiconductor, oil exploration and other fields. Diamond is an excellent optical material with high transmittance from X-ray to microwave, high hardness, high thermal conductivity, high chemical stability and low coefficient of expansion. Also diamond is an ideal semiconductor material with wide band gap, high carrier mobility, high breakdown voltage and high thermal conductivity.

Monocrystalline Diamonds – High Pressure High Temperature

MPCVD diamonds are high-quality single crystals with a growth rate of 50-150 mm/day, depending on the stage design and methane concentration. This process can also be used to compress large samples at ultrahigh pressures. The typical electrical and mechanical properties of MoSCAPs are discussed in this article. A brief description of the HPHT process is also provided. This method can also be used to create rare yellow fancy colored diamonds, which are highly valuable because they are created by the Gemesis process.

Gemesis-created yellow fancy-colored diamonds are very rare and thus very valuable

While most fancy colored diamonds are colorless, yellow diamonds are an exception. A diamond that is colored yellow is called a gemesis-created diamond. They are created by exposing a diamond to high levels of nitrogen in the mine. The process of creating this color results in diamonds that are more valuable than those that are colorless. Depending on the level of nitrogen in the mine, yellow diamonds may be light or intense.

While it takes several months for gemesis to create a diamond, the process produces an individual gem of top quality. Gemesis works with a team of experienced diamond cutters and leading jewelry manufacturers to develop each individual diamond. Moreover, the company has its own fine jewelry line. The company sells its products online, touting its “Create Your Own Jewelry” component. Parallel sales are made with select retailers.

Yellow lab-created diamonds are rare and valuable because they are not as plentiful as natural diamonds. The price of lab-grown diamonds is also lower than those created naturally. Yellow diamonds are produced by adding a brownish tint to diamonds. The process can be reversed by annealing or heating during jewelry repair. This treatment is not as intense as natural diamonds, but they are less expensive than natural ones.

Lab-created diamonds are much cheaper than natural diamonds, but they lack the vividness of natural yellow. Natural diamonds are formed over billions of years, but lab-created diamonds are created within a few weeks. A natural diamond’s deep yellow color will remain the same as its original color, despite the fact that it is much more expensive.

Natural fancy-colored diamonds are incredibly rare and valuable. However, a Gemesis-created yellow diamond is not only indistinguishable from a natural diamond, it can be purchased for less than four thousand dollars per carat, which is approximately 30% lower than a natural diamond. So if you’re looking for a unique and expensive diamond, you’ll have to search for one yourself.

HPHT process

One of the most important characteristics of HPHT and CVD synthetic diamond is their color. Most diamonds are brown or yellow, and colorless diamonds are rare and expensive. However, HPHT annealing can enhance the optical properties of some CVD diamonds and increase their hardness. Carnegie scientists have now created a transparent diamond without HPHT annealing. These findings are described in a paper to be presented at the Applied Diamond Congress in Argonne, Ill., on May 18, 2005.

The HPHT method combines a high pressure (5 GPa) and a high temperature (1,500degC) to create synthetic diamonds. The process requires a special press designed for this purpose. GE invented this recipe in the 1950s. This method produces a yellow-hued diamond that is highly resistant to tool wear and is suitable for jewelry and tools. However, pure white HPHT material is more expensive and is used for jewelry and tools.

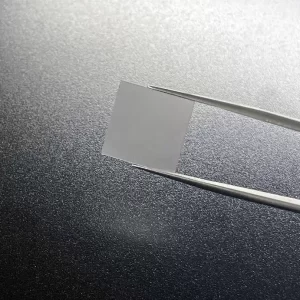

Researchers at the Carnegie Institution of Washington, D.C., have grown single-crystal diamonds as large as 10 carats. The researchers used a chemical vapor deposition process and produced 100 micrometers of diamonds per hour, resulting in a stone five times larger than commercially available diamonds. In a high-pressure/high-temperature process, the diamonds are produced in tiny crystals that are transparent from ultraviolet to infrared wavelengths.

The high-pressure, high-temperature technique has been developed for both industrial and scientific purposes. More refined methods of creating diamonds are being developed. Today, the HP-HT phase diagram can be built with greater accuracy. The process also allows for the production of thin layers of diamonds. The research has increased our understanding of diamond growth and produced many applications. The development of HP-HT techniques is progressing rapidly and is expected to yield more high-quality polycrystalline diamonds.

A second process involves the use of high-pressure high temperature (HP-HT) sintering techniques. The HP-HT process is the preferred technique for sintering large pieces of binderless diamonds. However, it is difficult to transfer the HP-HT process into industrial processes. But it is possible to produce diamonds of different colors with the HP-HT technique. It is an excellent alternative for synthetic diamond production.

Typical electrical characteristics of MoSCAPs

Typically, the resistivity of monocrystalline diamonds is very small, even at high temperatures and low voltages. This is due to the fact that the diamond’s drift region is very thin, so that the overall ON state resistance of the monocrystalline diamond is low. The other resistances, however, have a more significant effect on the performance of diamond power devices. These include contact, series, and access resistances.

The chemical processes involved in the formation of diamonds involve the recombination of carbon sources with sp3 bonds. Although the chemical transformation does not occur under disequilibrium conditions, diamond particles can be formed under unexpected P-T conditions. Diamond formation can be accelerated when the precursor materials undergo a process called sintering. This is possible when the nanostructure of diamond is increased by the introduction of diamondoids, which contain a larger number of sp3 bonds.

Chemical vapor deposition (CVD) is another way to produce monocrystalline diamonds. Diamonds made using this method can be extremely hard and have a high strength to weight ratio. It also has a relatively high degree of electrical conductivity. As a result, diamonds are often used in the fabrication of cutting tools and other products that require electrical characteristics. Typical electrical characteristics of monocrystalline diamonds yellow high pressure heat and pressure, including semiconductor devices.

In the past 50 years, diamond syntheses have largely relied on metal catalysts. These catalysts reduce the P-T conditions and have become the dominant type in the diamond industry. The synthesis of these materials is still controversial and outside the scope of this review. However, the basic principles of PDC are still the same. In a nutshell, catalyst diamonds are an excellent choice for manufacturing cutting tools and form dressers.

The first step in the diamond synthesis process involves introducing a carbon element into the polycrystalline structure. This process is known as a diamond-like transition. The graphite precursors sp2 and sp3 are favored for this process, and when the carbon is pure, the diamond transition occurs. The higher the crystallinity graphite, the more lonsdaleite is formed.

Friability of monocrystalline diamonds

The study of the friability of monocrystalline diamonds has helped us understand how these gemstones form. The differences in the chemical composition of diamonds are a result of the isotopic composition of carbon. Carbon contains two stable isotopes, 13C and 12C. The ratio of these isotopes varies according to the geologic processes and the original source of carbon.

The two main types of diamonds are those containing relatively low nitrogen content and yellow and black colour. These diamonds are relatively low in nitrogen, which reduces their colour. They are often classified as Type I diamonds, but their spectral properties differ from those of Type II diamonds. In this study, we’ll examine the differences between the two types of diamonds. Listed below are the main differences between the two types of diamonds.

The diamond cycle is intimately linked to the earth’s active geodynamics. Diamonds form in regions with a high carbon content. They form when peridotite is heated and becomes carbonated. This process also results in the melting of kimberlite, which is a material rich in carbon. The formation of diamonds depends on the mantle’s upwelling, which causes the occurrence of kimberlite.

Despite their varying properties, diamond is an efficient conductor of heat. Its specific gravity is 3.52, which makes them relatively stable. However, they are not the most stable solid carbon. In fact, graphite is more stable. The study of diamond is ongoing around the world. With occasional success, however, it is still a long way off from being used in making electronic circuits from diamonds.

As the size of diamond particles increases, they can be further broken down to smaller pieces. These particles can be used to polish a gemstone. Sapphire & Gemstone Polishing is another method used to polish diamonds. By using this process, the particles of a diamond can be reduced to a size of 1 um. This method allows the stones to retain their sparkle and luster. This method is effective for removing mineral inclusions that interfere with diamond growth.

1.0mm To 4.0mm HPHT Monocrystalline Diamonds Yellow High Pressure High Temperature