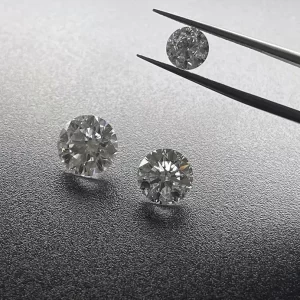

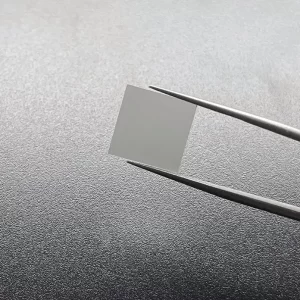

7mm*7mm Single Crystal CVD Lab Grown Diamonds Colorless

7mm*7mm Square Shape Optical Grade Single Crystal CVD Lab Grown Diamonds

Single Crystal CVD Lab Grown Diamonds Description

Chemical vapor deposition (CVD) is a common method for making of thin film materials. It uses the chemical reaction of vapor precursor under specific conditions to deposit the required thin film materials on a specific substrate. In the preparation of single crystal diamond materials, methane and hydrogen are usually used as precursors to grow single crystal diamond by gas phase epitaxy at high temperature (about 1000 ℃), atmospheric pressure (1 ATM) or low pressure. The single crystal diamond substrates used can be natural diamond, HPHT diamond or CVD diamond.

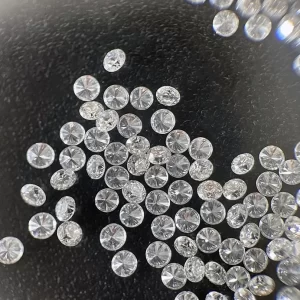

The appearance and composition of CVD diamond are almost the same as that of natural diamond, and the physical and chemical properties are not very different. Under the naked eye, there is no difference between CVD diamond and natural diamond. However, the main reason why CVD diamond is valued is that it is “pure”. Compared with natural diamond, CVD diamond is cleaner and has almost no impurities.

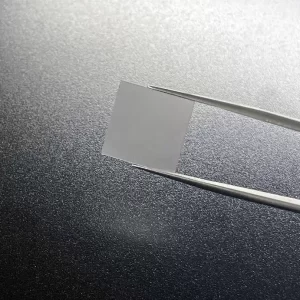

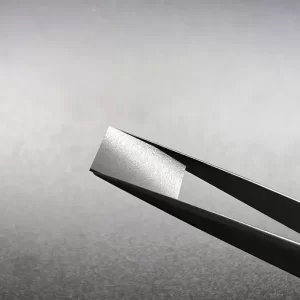

Surface: As Grown Or Laser Cut

Thickness: 0.5mm

Edge: Laser Cut or Polished

Size: 7*7mm, can customize

Application: For Making Tools

Crystal Orientation: 100 110 111

Single Crystal CVD Lab Grown Diamonds

How are Single Crystal CVD Lab Grown Diamonds created? Scientists at the Carnegie Institution in Washington, D.C. have used chemical vapor deposition (CVD) to grow diamonds up to a half-inch thick. The diamonds are characterized by their colorlessness and transparency from the infrared to the ultraviolet. Inclusions and growth structure are also described in this article.

Colorless

A GIA diamond expert can tell the difference between a natural and a CVD diamond, based on their unique growth patterns. HPHT diamonds are formed into a cuboctahedron with fourteen growth directions, while CVD diamonds are cubic in shape. Both processes have their disadvantages, though. In particular, HPHT diamonds have a higher percentage of colour than CVD diamonds, and the latter sometimes show evidence of strains. Nonetheless, both methods are now capable of producing colourless diamonds.

The process of lab-grown diamond growth is similar to the growth of natural diamonds. As a result, lab-grown diamonds can vary in color and clarity. Not all of them are colorless or flawless. Regardless of their color, however, all lab-grown diamonds are graded using the same standards and criteria used for mined diamonds. These diamonds are examined and graded by the same independent gemological laboratories as earth-extracted diamonds.

A SC-CVD diamond is grown sequentially on six hundred faces of an HPHT Ib substrate. This method attempts to increase the size of diamond crystals by removing unfilled areas during the growth process. In the end, a SC-CVD diamond produced by this method is nearly 300 carats in weight and one inch in diameter. While the growth process is challenging, the result is a diamond with high optical properties and little to no impurities.

The main process controller can control the temperature gradient across the growth surface of the diamonds. It can be controlled using temperatures in the growth surface at the edges and the middle. By using these temperature gradients, it is possible to increase the growth rate of single crystal CVD diamonds by up to 50 microns per hour. However, this technique requires considerable expertise in the production of diamonds. You may want to consult a professional before you begin this process.

Limited in terms of specifications

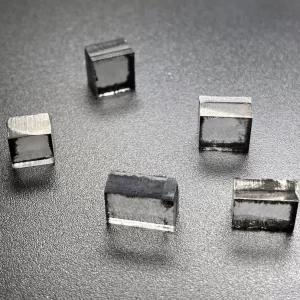

CVD laboratory-grown diamonds are limited in terms of the crystallographic orientation of their crystalline growth faces. Changing the gas pressure, temperature, or chemical composition of the CVD reactor can alter the diamond’s geometry. Changing these conditions can affect the crystallographic orientation and, therefore, the shape of the diamond. The growth surface of a single crystal diamond is usually larger than the substrate.

The initial material is substantially square with a hundred surface areas. Growth takes place on the upper 001 surface, predominantly. The subsequent base material cut from the grown diamond material is also square in cross section, with 110 edges. As the CVD process continues, the size of the next 111 surfaces increases and the shape of the diamond changes. The result is a cubic, symmetrical diamond.

The length of the longest linear internal dimension (LID) of a single crystal CVD laboratory grown diamond is the longest distance a straight line can travel inside it. This distance is known as the body diagonal of a cube. The length of the longest linear internal dimension is also called the ‘length of the cube’. By measuring the length of the diamond crystal, it is possible to see how much of each component is different from another.

Another significant limitation of this technique is its low selectivity and limited size range. Single crystal diamond substrates are only available in a limited range of sizes and specifications. The most recent experiments report an etch rate of forty um/h (one-hundred micrometers) and an etch depth of 55 um. The etching process can be parallelized, allowing for standard microfabrication and parallelization of micromechanical components.

Inclusions

The chemical structure of diamond inclusions is unknown. Researchers are rapidly expanding the field of synthetic diamond research. These new types of samples are making their way into the diamond trade. Some inclusions in synthetic diamonds pass for natural inclusions under a microscope or 10x loupe. Nevertheless, their fluorescent patterns are difficult to interpret without extensive knowledge of the chemical structure of natural diamonds. Here are some common types of synthetic diamond inclusions.

Single crystal CVD diamonds are a result of a process where multiwalled carbon nanotubes are placed on the surface of the diamond particles. The process results in the growth of diamonds with a different atomic structure than conventional diamonds. It also involves adding nitrogen to the diamond to prevent defects and enhance growth rates. Nitrogen is added at a ratio ranging from 0.1 to 5%.

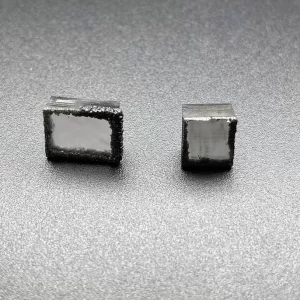

Inclusions in CVD diamonds vary from very faint to intense. The presence of a single sharp graining plane is a common example. However, the presence of this type of inclusion is not diagnostic for separation. The metallic flux inclusion is the most common type of inclusion and has a highly reflective luster. The presence of a metallic flux inclusion can also be determined by examining the diamond’s opacity and luster under fiber optic illumination.

Single crystal CVD diamonds contain small amounts of tungsten, carbon, and nitrogen. The inclusions are mostly black and reflect light. The difference in material makes no practical difference when choosing between HPHT and CVD diamonds. Both processes are designed to produce clean diamonds. The inclusions in single crystal CVD lab grown diamonds dispel the myth that synthetic diamonds are more perfect than natural diamonds.

Growth structure

The growth structure of natural and CVD diamonds is very different. Natural diamonds exhibit an irregular ring-like growth structure whereas CVD samples show lamellar growth. This study provides the experimental basis for the identification of synthetic diamonds. Natural diamonds have a blue fluorescence due to the presence of aggregated nitrogen. Hence, it is important to distinguish between natural and CVD diamonds.

Diamonds are deposited sequentially on six hundred-faceted HPHT Ib substrates. Each successive layer of diamond 136 has a diameter of one inch, allowing for the formation of a large single-crystal diamond. It can reach 300-carats and 1 inch in each dimension. However, the growth process can be slow and inefficient when the sheath is too thick or too thin.

To make a diamond, the main process controller regulates the temperature of the surface. It also determines the gradient of temperature across the growth surface, and if the diamond needs to be repositioned. Another important factor is the control of gas and coolant flows. The main process controller also controls the flow rate of the reactant. It also determines the degree of resonant power of the plasma.

Although the growth structure of single crystal CVD lab grown diamond is completely different from natural diamonds, both types have similarities and differences. For example, single crystal CVD diamonds have a planar graining pattern similar to those of natural diamonds. This characteristic is known as a planar inclusion and is not easily identified. However, planar inclusions are distinguishable, because they are distinct remnants of the CVDs layered past. Another characteristic of these inclusions is their reflective luster.

Chemical vapor deposition technique

The process of synthesis of colorless diamonds uses the Chemical Vapor Deposition (CVD) method. Diamonds are formed layer by layer in the CVD process. The resulting diamonds are colorless and have a unique optical quality. The main characteristic of CVD diamonds is the absence of strain lines. As a result, these diamonds are more transparent and less prone to the brown hue. This technique can produce diamonds with a VS1 clarity grade.

During the growth of single crystal CVD diamonds, the plasma overconcentrates at the boundary of the substrate, resulting in severe polycrystallization around the crystal. This severely limits the usable area of the single crystal. The small size of the synthetic diamond makes it difficult to meet the demands of industrial applications. The quality of the epitaxial diamond layer is also limited by dislocation accumulation and twinning. Hence, it is difficult to produce colorless diamonds at a high growth rate.

This technique is used to grow diamonds in the labs. CVD produces diamonds of high purity. The diamonds are colorless and transparent from UV to infrared wavelengths. However, some types of diamonds exhibit brown or blue tints. In such cases, the defects in the diamond are harmful to its exceptional optical, electronic, or spintronic properties.

In 1962, Eversole et al. first proposed the gas-based diamond growth technique. During the growth, the substrate is covered with amorphous carbon. Similarly, Spitsyn et al. reported a thin epitaxial layer of diamond. These researchers also discussed the role of hydrogen in the process. The process of creating single crystal diamonds was later modified to create a more uniform and high-quality product.

7mm*7mm Single Crystal CVD Lab Grown Diamonds Colorless