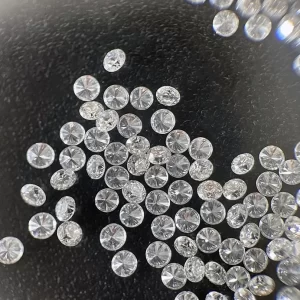

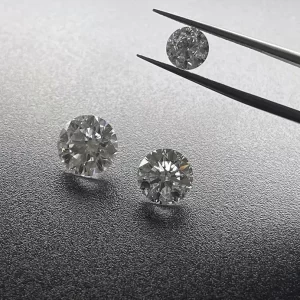

Yellow 3.4mm Synthetic Single Crystal Hpht Diamonds For Industrial Applications

Single Crystal Hpht Diamonds Description

Lab diamonds are real diamonds. Carbon is the main element of natural and laboratory-grown diamonds. The chemical and physical properties of synthetic diamonds are same as natural diamonds in terms of hardness, thermal conductivity, and strength.

High temperature and high pressure (HPHT) and chemical vapor deposition (CVD) are the two most commonly used growth methods in synthetic diamonds industrial. High temperature and high pressure exert intense heat (about 1500 degrees Celsius, or 2700 degrees Fahrenheit) and pressure (1.5 million pounds per square inch) on the diamond seed and the carbon atoms surrounding it. Chemical vapor deposition, on the other hand, uses less heat and pressure, but introduces a mixture of chemical gases, which decomposes and hardens into crystalline carbon atoms.

Diamond is the most stable material in density. Because of its simple chemical composition and compact structure, the density of transparent diamond has the greatest stability, and the range of density variation is only about 0.01% when it contains impurities. This characteristic is of special significance for gem identification.

Diamond is the most inert material. Thermal inertia is the nature of maintaining the thermal motion state of matter. The greater the thermal inertia, the more difficult it is to change the thermal state. Diamond has the highest thermal conductivity and the highest thermal inertia, which can not be compared with any metal and non-metallic minerals. This provides a basis for the design of thermal test instrument. It is quick and effective to distinguish diamond from other gemstones by thermal conductivity meter.

Yellow 3.4mm HPHT Synthetic Single Crystal Diamonds Industrial Applications

HPHT Synthesis of Single Crystal Diamonds

High pressure, high temperature (HPHT) synthesis of diamonds is the first step to producing these gem-quality stones. This process involves the application of high pressures of five to six GPa to grow the crystals. Appropriate systems are required to stabilize temperature and pressure. Growth time can be anywhere from several tens to hundreds of hours. Typically, the time span is between 50 to 200 hours.

High pressure, high temperature (HPHT) synthesis

The HPHT synthesis of single crystal diamonds is the process of creating large, high-purity, monoclinic diamonds by introducing an elemental nitrogen gas into a liquid at elevated pressures. The process involves controlled doping and pressure stabilisation systems. It may take hundreds of hours to grow a single crystal. It is possible to create single crystal diamonds with tuned morphologies. HPHT synthesis of single crystal diamonds is a promising method for making these large, complex stones.

The seed must contain at least 30% single growth sector and preferably 80%, 85%, or 90% single-growth sectors. The seed will preferably have fewer defects than a single-crystal diamond and fewer extended defects propagating from growth sector boundaries. HPHT synthesis of single crystal diamonds may be carried out by a solvent-free process. The HPHT method is also applicable to a variety of other materials.

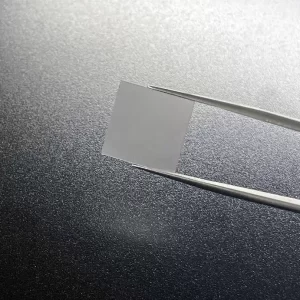

The HPHT method produces single-crystal diamonds with faces parallel to the surface of seed crystal growth and the longest dimension is greater than two micrometers. The method of HPHT may be pressure or temperature driven. Pressure-driven methods may also be used, such as phase-balance synthesis and graphite conversion. All three methods are performed at temperatures ranging from 1280 to 1390 degrees Celsius.

The HPHT method described in WO2008/107860 produces synthetic single crystal diamond material with reduced metallic inclusion content. During the synthesis process, the seed must have a high aspect ratio, at least 1.5, in order to generate a high-quality single-crystal diamond material with the desired abrasion resistance, long edges, and crystallographic orientation properties. A simple and cheap method is necessary for producing high-quality single crystal diamond material with such properties.

The first test for HPHT synthesis was the production of multiple single-crystal diamonds on 24 HPHT synthetic type Ib seeds. This process required a DC-GD-CVD system that employed a gas mixture of CH4-H2-Ar to raise the temperature and density of the plasma. The plasma formed diamonds at 900-950degC and grew uniformly on the seeds.

Morphology

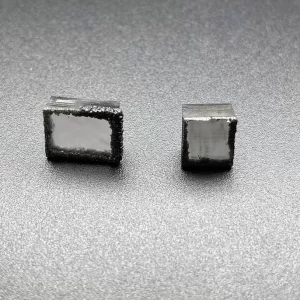

Raman spectra recorded at room temperature showed the NV0 defect, the first order phonon peak in the diamond’s NV-doped layer. The nitrogen-doped layer shows higher compressive stress compared to the buffer layer. Figure 3b shows the triple density of NV0 defects. Inset: SIMS spectra of a cross section of a single crystal sample. The nitrogen-doped layer exhibits the highest nitrogen concentration, 20.5 ppm, while the buffer layer has the lowest.

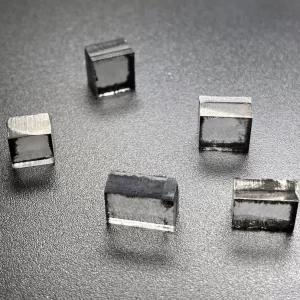

The morphology of HPHT synthetic single crystal diamonds can be described using a scale called the crystal morphology index (CMI). CMI refers to the fractional cutback at a cube corner in plan. The scale goes from zero to eight. A perfect cube has a CMI of 0 while a perfect octahedron has a CMI of 8. The longest dimension of a crystal is called the major face.

The seed crystallographic orientation of a synthetic single crystal diamond material influences its morphology. For instance, a cubic seed will result in a square-faced block as the final shape. Conversely, a 110-oriented plane will result in half of a hundred-faced cube cut diagonally. As a result, a high-quality HPHT synthetic single crystal diamond material can be produced with minimal processing.

HPHT synthesised diamonds exhibit unique properties related to the presence of oxygen and hydrogen. Using photoluminescence spectroscopy, these diamonds show characteristics related to incorporation of metal atoms in the diamond lattice. The main experimental conditions used ranged from 1500 degC to 1650 degC, and C6H8O7 concentrations were 0 to 1.0 wt%.

High quality synthetic diamonds have at least one long dimension, making them useful for tool applications. This means that the synthesis process is long, increasing the risk of hardware control failure and growth variation. The seed has been reduced by a significant amount to allow for growth space, resulting in intensive use of industrial synthesis capacity and decreased availability on the market. So, what is the synthesis process of HPHT synthetic diamonds?

The external morphology of HPHT synthetic single crystal diamonds produced using the method described in the present invention is predominantly octahedral. The stone’s surface is made up of at least ten percent of planes of the 100-type, while the remainder is comprised of eleven, 113, and 115-type crystals. The morphology of HPHT synthetic single crystal diamonds obtained using this method exhibits higher fracture toughness compared to the HPHT seed substrate and the unintentionally doped CVD single crystal diamonds.

Size variation

The size variation of HPHT synthetic single crystal diamonds is a challenging problem. The initial bulk was composed of B doped quartz and was characterized by low resistance. This variation was further accentuated by the presence of many dislocations and stacking faults. Later, HPHT synthetic single crystals were grown using a CVD process, which decomposed the carbon atoms to form a diamond.

The size variation of HPHT synthetic single crystal diamonds can be traced to its underlying grain structure. High-quality crystals larger than 3 carats are difficult to produce by conventional methods. Several groups have begun to grow diamond single crystals by CVD. The fabrication of a half-inch-sized, 10-carat CVD diamond was a significant breakthrough. The findings were presented at the 10th International Conference on New Diamond Science and Technology in Tsukuba, Japan, and will be presented at the Applied Diamond Congress in Argonne, Illinois.

A major advantage of this technology is the reduction of impurities by adding oxygen to the CVD stage. Oxygen adds lower temperature and removes nitrogen-related impurities. This process also yields diamonds with low silicon and hydrogen content. It also allows for a lower growth rate of ten millimeters per hour compared to the standard process, which has a growth rate of less than 0.3 mm/h.

The size variation of HPHT synthetic single crystal diamonds varies depending on their intended applications. Early-stage devices with high dislocation densities are suitable for 10 A testing. However, it is necessary to test 10 A devices with diamonds before making the final decision. The results of this research should help industry develop new materials and improve current and voltage standards. There are several challenges ahead, including the size variation of HPHT synthetic single crystal diamonds.

The HPHT process was first developed in the 1950s for industrial purposes. Today, it is used to enhance mined diamonds. It mimics the natural environment of diamond crystal formation, which lasted 150 million years before it became naturally formed. By comparison, HPHT diamonds can be a significant 40% cheaper than natural diamonds and can be sourced from an eco-friendly environment. So what are the advantages of man-made diamonds?

Control of inclusion uptake

There are some unique characteristics of synthetic diamonds produced with HPHT methods, which we identified using photoluminescence spectroscopy. These unique features are associated with the incorporation of metal atoms from the catalyst metal into the diamond lattice. This work provides important insights into how nitrogen affects these features. We also investigated the effect of Ti on the nitrogen state. The results suggest that the nitrogen concentration in HPHT diamonds can be controlled to enhance their quality.

In this method, the seed is selected so that its aspect ratio is at least 1.5. In addition, the present inventors found that the synthetic single crystal diamond produced by this method had a decreased metallic inclusion content. The invention relates to an improved method for producing a high-quality single crystal material with long edge length, excellent abrasion resistance, and high crystallographic orientation. The present invention provides a practical solution to these challenges.

To produce the desired quality, the seed’s surface was polished. The Ra measured with a stylus profilometer was less than 100 nm. This seed was incorporated into an HPHT press capsule, with the seed and Ni, Fe, Co, and C. This HPHT press capsule was then ramped to a synthesis pressure of 5.5 GPa at a temperature of 1310deg C. This temperature was chosen to target a cold morphology.

The as-synthesised single crystal diamond material also contains at least one dominant growth sector. In addition, the external surface of the synthetic single crystal diamond must be substantially parallel to the seed face. In addition, the synthesised single crystal diamond material may contain one or two spectroscopically visible inclusions. The as-synthesised material also comprises more nitrogen than the prior art method.

Controlling inclusion uptake is a major step in the development of high-purity synthetic diamonds. Inclusions can be selectively controlled and the NV/Ns ratio can be controlled. This will allow a higher doping efficiency and improved crystalline properties. Moreover, this approach may allow industrial production to be more consistent and reproducible. It is important to keep in mind that diamonds with high NV/Ns ratios should be enriched with the same dopant and increase crystalline

Yellow 3.4mm HPHT Synthetic Single Crystal Diamonds Industrial Applications quality.