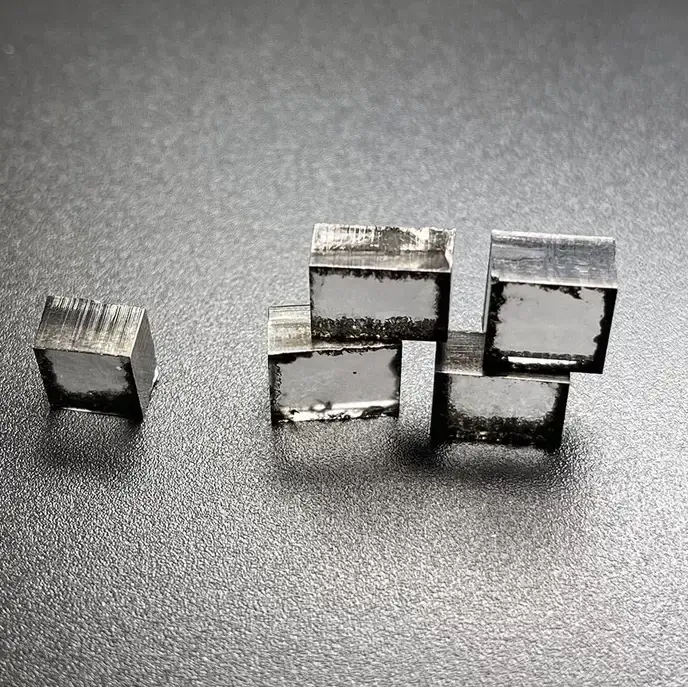

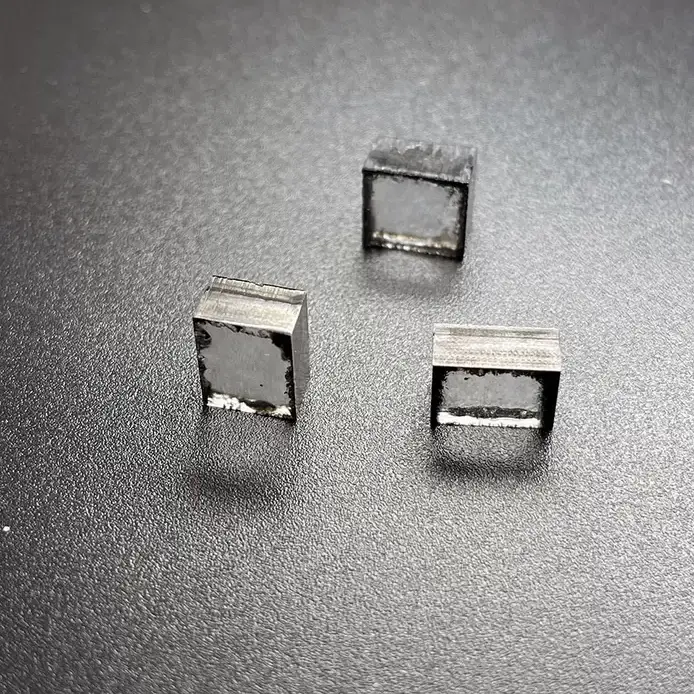

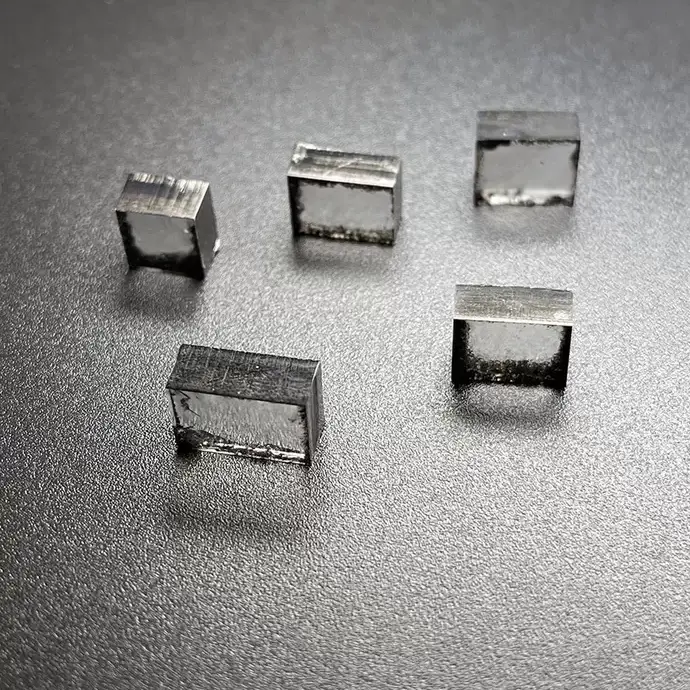

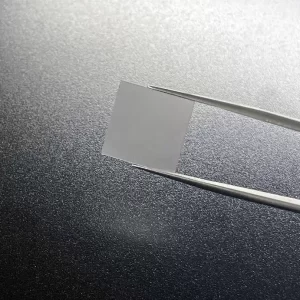

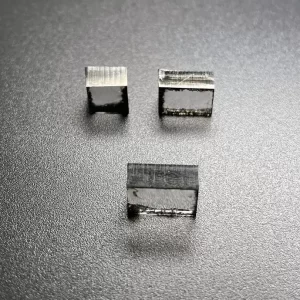

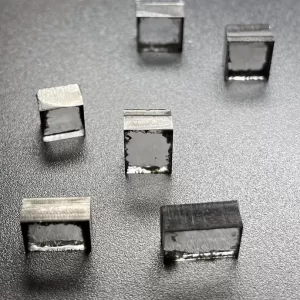

9mm 11mm GHI Color CVD HPHT Raw Uncut Diamond 8.0ct To 8.99ct

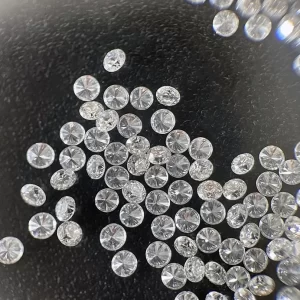

Square Shape 9mm – 11mm GHI Color Cvd Hpht Uncut Rough For Making Round Brilliant White Color Jewelry

CVD Lab Grown Diamonds Description

Laboratory-grown diamonds, also known as laboratory-made diamonds, man-made diamonds and synthetic diamonds, are pure carbon diamonds that simulate the natural growth process of the earth under strictly controlled laboratory conditions.

What is high pressure high temperature (HPHT) diamond?

HPHT stands for High Pressure High Temperature Method, which is a main method used in laboratories to make diamonds. This diamond growth process requires carbon to be exposed to extreme temperature and pressure conditions, which simulate the extreme heat and pressure conditions when natural diamonds are formed in the depths of the earth.

The diamond seed crystal is placed under specially designed pressure conditions, and the growth chamber is heated to 1300-1600 °C, and the pressure is higher than 870,000 pounds per square inch (approximately 5,998,440 Pa). The molten metal decomposes high-purity carbon sources and deposits carbon atoms in one place. After the synthetic diamond starts to grow on a small diamond seed crystal, this laboratory-made crystal is cut by a diamond cutter.

In detail, HPHT diamonds are grown in a small chamber, which is located in a device that can generate extremely high pressure. The carbon raw materials (such as graphite) in the cabin are melted in a metal co-solvent composed of iron (Fe), nickel (Ni), cobalt (Co), etc., thereby reducing the temperature and pressure required for diamond growth. Then, the carbon material moves to the lower temperature diamond seed crystal with the help of the co-solvent, and crystallizes on it to form a synthetic diamond crystal. The crystallization process takes several days to several weeks to form one or more crystals.

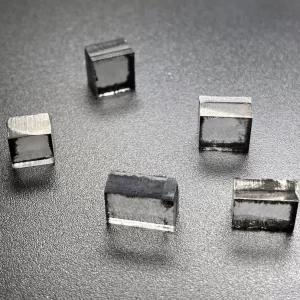

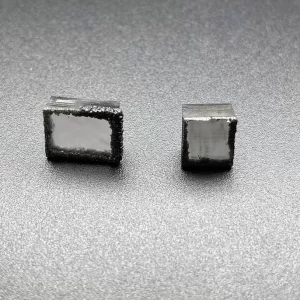

Natural diamond crystals are often octahedrons, while HPHT synthetic diamond crystals usually have cubic surfaces in addition to the octahedral surface. Due to the different shapes of natural diamond crystals and HPHT synthetic diamond crystals, their internal growth patterns are also quite different. The difference in internal growth mode is a reliable way to distinguish natural diamond crystals from synthetic diamond crystals.

Synthetic gemstones that have been faceted usually show special color distribution characteristics, fluorescence partitions and twinning patterns, which are all related to the cross-shaped growth zone structure of the crystal. Sometimes this type of gemstone will also have dark metallic flux inclusions. In some cases, this material will exhibit phosphorescence, that is, after being exposed to an ultraviolet light source, it can continue to emit light even if the light source is turned off.

The production of colorless HPHT synthetic diamonds was once a big problem. Nitrogen turns diamonds yellow, so it must be excluded from the growing environment. In addition, high-clarity colorless diamonds require a longer growth time, and the temperature and pressure conditions required for their growth also need better control.

CVD Or HPHT Raw Uncut Diamond

When purchasing a rough diamond, the best way to decide whether to buy a CVD or an HPHT model is to first understand the process of creating them. In this article, you will learn about the costs, growth morphology, and treatments that are used to make diamonds near-colorless. Then, you can decide whether you want to invest in a diamond that has been cut and polished or go for an uncut version.

Process of creating lab-grown diamonds

A diamond is formed by fusing carbon atoms and other elements that make up the earth’s mantle. Diamonds can be grown in the lab by experts who recreate the conditions that diamonds form naturally. This process requires temperature ranges from 700 to 1300 degrees. The diamonds are grown in a chamber where scientists pump carbon-filled gas into a high-pressure chamber. The atoms are then deposited on the diamond seed to form a crystal.

Unlike natural diamonds, man-made diamonds do not contribute to the environment by mining them. Unlike natural diamonds, which are mined and harvested from forests, they do not contribute to air pollution or soil erosion. And, unlike natural diamonds, lab-grown diamonds don’t require massive amounts of pressure and temperature. Natural diamond mining requires massive machinery and a huge amount of natural resources. A lab-grown diamond is created with cutting-edge technology and will not devastate natural ecosystems.

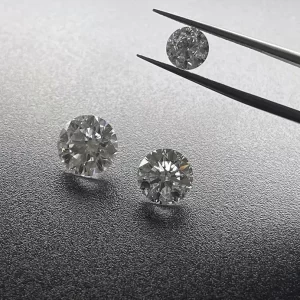

Another important factor is the cut. A good diamond is a perfect example of a brilliant stone. Whether a lab-grown diamond is perfect or not will depend on its cut. A perfect diamond is colorless or has an unusual color. Clarity means that a diamond is free of imperfections. A diamond with a perfect clarity grade is ideal for jewelry. A flawless diamond is rare and worth a great deal.

One of the most common methods for growing diamonds in a lab is ultrasound cavitation. This technique involves exposing graphite to high-pressure sound waves to produce diamonds. Although the yield from this technique is relatively low, experts are working on improving the procedure to increase the yield and lower the cost of the diamond. In some cases, the amount of carbon that the diamond produces is lower than the natural one.

The main advantage of lab-grown diamonds is their affordability. The prices of diamond jewelry are significantly lower than those of their natural counterparts. Additionally, lab-grown diamonds have a higher quality than their natural counterparts. The process of creating lab-grown diamonds involves a careful selection of raw materials and a rigorous testing process. Unlike diamonds, the cost of lab-grown ones can be much more affordable than their natural counterparts.

Cost

If you’re in the market for a diamond, you might be wondering how the process differs from a natural stone. Both types of diamonds can be faceted or cut, which is why some customers may be tempted to purchase an HPHT diamond. However, a natural diamond has some unique characteristics that distinguish it from a CVD diamond. These characteristics include the shape and morphology, which is what distinguishes one type of diamond from another.

Natural diamonds formed millions of years ago, while lab-grown diamonds are created in just a few weeks. The morphology of diamonds grows differently depending on the conditions under which they were created. The process used to make CVD diamonds is known as chemical vapor deposition. This technique mimics the process that diamonds would have undergone if they were formed in interstellar gas clouds.

As mentioned, the process of growing diamonds is more complicated and costly than producing diamonds naturally. A diamond grows from a raw stone, which is the hardest material on Earth. This process involves the use of multi-million dollar laser tools and requires highly trained technicians and PhDs to operate. The machines are expensive, ranging from $250k to a million dollars. However, they are worth it, as they guarantee high-quality diamonds.

The method of creating a diamond using a chemical vapor deposition (CVD) technique is the best way to obtain a diamond with the best qualities without spending a fortune. It produces high-quality diamonds with a variety of color and clarity. This type of diamond is very rare and will only last a lifetime. In addition to that, it will not cost much to own one of these diamonds.

The cost of a CVD diamond can range from $10 to $4000 depending on a few variables. A high-quality CVD diamond will typically cost at least two million dollars, but the process of growing diamonds with HPHT technology costs more. It is also less expensive than a natural diamond. A rough CVD diamond will cost approximately four times that amount. If you’re interested in buying an HPHT diamond, it’s a great idea to contact a certified lab.

Growth morphology

The morphological characteristics of mined and lab-grown diamonds are quite similar, however, there are a few differences. One major difference is the crystallographic shape. While mined diamonds may have various shapes, the growth morphology of lab-grown diamonds is more uniform and predictable. A company called Ultra C has been collecting rough diamonds from 10 different diamond growers and carrying out polishing and cutting. The yields of the raw diamonds are based on these experiments and are thus lower than the production yield of naturally-grown diamonds.

The morphological structure of the CVD HPHT Raw Uncut Diamond is determined by the growth rates of the major crystalline faces. These faces are 100, 111, and 311. According to the crystal growth laws, the area fraction of the face with minimum growth rate increases. Hence, the greater alpha-parameter a, the more 111 face area is present. The crystalline faces of CVD diamond are generally symmetrical.

Unlike natural diamonds, the diamonds grown using HPHT undergo a process called carbonization under high pressure. This method makes diamonds with a blue nuance. The blue nuance is caused by the inclusion of boron, which is also a component of fancy blue diamonds. HD videos and images can clearly show this effect. In the 1980s, this method was developed to simulate the formation of diamonds in interstellar gas clouds. In contrast to HPHT, CVD uses less pressure and smaller machines.

The addition of nitrogen to the growth mixture increases the rate of growth and the probability of the formation of two-dimensional nuclei on the growing surface. Hydrocarbon supersaturation facilitates the growth of nanocrystalline films. The final product shows the unique characteristics of diamond growth. A study of this method shows that it is possible to produce diamonds with a higher quality than a conventional process.

While natural diamonds grow in millions of years, lab-grown diamonds are formed within weeks. Growth morphology of HPHT and CVD-created diamonds differs considerably, and the crystal shape of each type depends on the conditions during their growth. This difference was explained by GIA Senior Research Scientist Dr. Sally Eaton-Magana. She emphasized that the growth morphology of CVD diamonds is less predictable than that of HPHT diamonds.

Treatments required to make them near-colorless

Although some gemological laboratories have been using this method since the mid-1990s, it was not until 1999 that this process was introduced into the jewelry industry. In 1999, General Electric and Lazare Kaplan International founded Pegasus Overseas Ltd. to market treated gems. Today, this company is known as Bellataire Diamonds. Several other companies also offer HPHT treatments, including Novatek in Provo, Utah, and Phoenix Crystal Corp. in Ann Arbor, Michigan.

The first method of clarity enhancement was developed by Yehuda Diamond Co. and has since become a common treatment for diamonds. Thousands of carats of diamonds are treated each year by several companies. The “flash effect” is visible on the diamond’s surface, and is a characteristic color that appears against a bright or dark background. While it does not have the full spectrum of color, this effect is visible at 10x magnification and in close-up view of an intense light beam.

Another method is a post-growth treatment that uses high pressure and high temperature. This method seals microscopic voids created during growth. As a result, HPHT diamonds tend to have black flux inclusions. However, this is a relatively recent development and time will tell whether CVD diamonds will reach the size of their HPHT cousins.

The color of the first gem-quality stones was always yellow to brown due to nitrogen. Inclusions were common, including nickel-like plates. However, after removing the nitrogen, the process was able to produce colorless “white” or “blue” diamonds. This process, however, also slowed the growth process and reduced crystalline quality. But these new methods are far from perfect.

Another procedure is the High Pressure/High Temperature (HPHT) process. This process involves exposing a mixture of elements to extremely high temperatures. This causes the atoms in the mixture to rearrange themselves into new structures. This process has been around since ancient times, but has only recently been widely used. It has also become common in jewelry stores around the world.

9mm 11mm GHI Color CVD HPHT Raw Uncut Diamond 8.0ct To 8.99ct