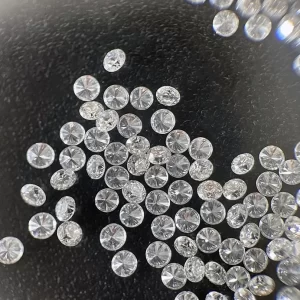

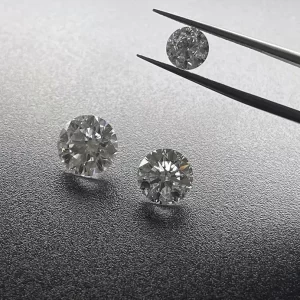

2mm Yellow HPHT Monocrystalline Diamonds Industrial

Yellow Color HPHT Monocrystalline Diamonds For Industrial Usage

HPHT Monocrystalline Diamonds Description

Lab diamonds are real diamonds. Carbon is the main element of natural and laboratory-grown diamonds. The chemical and physical properties of synthetic diamonds are same as natural diamonds in terms of hardness, thermal conductivity, and strength. High temperature and high pressure (HPHT) and chemical vapor deposition (CVD) are the two most commonly used growth methods in synthetic diamonds industrial.

Lab diamond is not only of high commercial value, but also widely used in industry.

The diamond we know used in industry is usually glass knife. Because of its high hardness, HPHT Monocrystalline Diamonds can easily cut glass. But diamonds also wear out, so sometimes we grind them to cut glass better.

Because of its high hardness, synthetic diamonds are often made into wire drawing dies, which are used to make copper wires of various thicknesses. For example, the fine copper wires in wires are drawn by diamond eye dies, which are highly practical in industry.

Diamond is an ideal optical material and semiconductor material. It has high hardness, high thermal conductivity, high stability, low expansion coefficient, wide band gap, high breakdown voltage and high carrier mobility

In aviation industry, gyroscopes, laser metal mirrors, magnetic heads of video recorders and sun drums of copiers all have very high requirements for surface smoothness and accuracy. The characteristics of diamonds fully meet the above requirements. They can not only produce natural diamond tools, but also make the ultra precision mirror cutting technology flourish.

Diamond Size: 2mm

Mesh Size: 8/10

HPHT Synthetic Diamond Seeds

High-pressure chemical vapor deposition (HPHT) is a method of forming diamonds from synthetic materials. In this article, we will look at its manufacturing process, production methods, and applications. We’ll also discuss the characteristics of HPHT synthetic diamond seeds. This technology produces synthetic diamonds that are shaped like real diamonds and are a valuable alternative to natural diamonds. The main benefit of HPHT synthetic diamonds is their high-quality growth properties.

High-pressure chemical vapor deposition (HPHT)

High-pressure chemical vapor deposition (CVD) is a process for the production of single-crystal diamonds. Its remarkable properties include low thermal expansion, exceptional hardness, wide spectral band, and electrochemical behavior. CVD methods have potential applications in astronomy and other industries. Currently, CVD is a popular choice for producing monocrystalline diamonds.

LPHT annealing can increase the intrinsic hardness of diamonds by two and fracture toughness by four. Enhanced diamond hardness may enable the development of new technology. Enhanced diamond toughness and increased thermal conductivity may enable new applications for diamonds. A low-cost alternative to HPHT annealing might soon be developed. However, this process has some drawbacks.

MPCVD diamonds can be high-quality single crystals with a high growth rate. The growth rate of single-crystal MPCVD diamonds can range from 50 to 150 mm/h depending on the stage design. Additionally, MPCVD techniques are suitable for producing large single-crystal anvils. These benefits have prompted considerable interest in the development of single-crystal CVD diamond growth procedures.

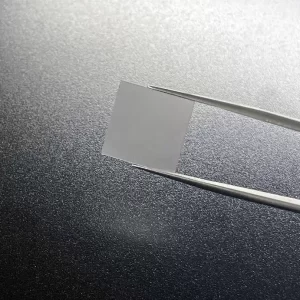

The method can prepare single-crystal diamonds of various dimensions. Depending on the desired thickness, these diamonds can be of a single crystal diamond size of one to two carats. The thickness can be anywhere between 10 to twenty-five millimeters and up to eighteen millimeters. Deposition pressure can be controlled by a PC with LABVIEW software. During the process, substrates were commercially available 3.5 x 1.6 mm3 HPHT synthetic type Ib diamonds. For the most representative results, deposition pressure was set at 300-350 torr. Using this pressure range provided the fastest growth rate.

The MPCVD process involves a microwave plasma, a carbon source, and an oxygen source. The plasmas grow at a rate of two to four millimeters per hour. When the plasma density is increased above 400 torr, it becomes more difficult to maintain a uniform growth rate. The method is best applied on a substrate that is resistant to arcing.

Characteristics

HPHT-processed diamonds have several unique features that distinguish them from other synthetic materials. These unique features are determined by photoluminescence spectroscopy, which is used to measure the amount of metal atoms incorporated in the diamond lattice. HPHT-produced diamonds are a valuable alternative to natural diamonds for industrial applications. The following is an overview of the characteristics of HPHT-processed diamonds.

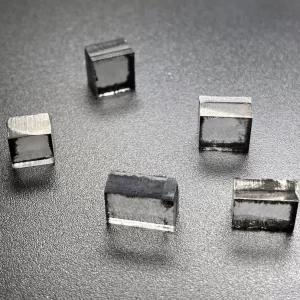

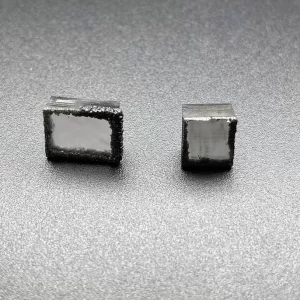

The high-pressure, high-temperature process of single-crystal diamonds results in two distinct morphologies: cold and hot. The cold morphology of HPHT-processed diamonds is suitable for applications such as chisel dressing, single point dressing, and high abrasion resistance. The hot morphology of HPHT-processed diamonds is best suited for industrial applications such as cutting tools.

High-pressure-high-temperature annealing is a common commercial method of altering the optical properties of natural diamonds. This process requires high temperatures ranging from 1800 to 2500 degC to prevent graphitization. Although the origins of these changes in the diamond are unknown, the reduction in visible absorption is thought to be due to the removal of strain induced by plastic deformation. This is due to the release of vacancies by dislocations.

The as-synthesized material should be homogeneous in shape. The nitrogen content and growth sectors affect the optical properties of the diamond material. The nitrogen solubility is higher in the growth sectors of 111 and 110. In addition, cold morphology is required in some applications. Optical property is an important characteristic of high-quality diamonds. If the morphology of the final product is uniform, the quality of the finished product will be high.

IR spectroscopy is an extremely useful tool for identifying impurities and defect species in the diamond. LPHT annealing changes many hydrogen-related transitions. IR absorption spectra reveal a C-H stretching region in the range of 2800-3200 cm-1, and a broad band in the same spectrum at 2930 cm-1. This broad band is attributed to hydrogenated amorphous carbon and correlates with the brown color of the diamond.

Production

HPHT monocrystalline diamonds are synthetic single crystal diamons that are produced by a high pressure and high temperature synthesis. Due to their tightly controlled growth conditions, these diamonds have various morphologies. They are available in the forms of rectangular, triangle, round and sex-angle. In addition, they can be cut into gems. In addition to gem-quality diamonds, HPHT-produced diamonds are also available in a wide range of colors.

Using nickel-containing solvent catalysts for diamond synthesis, FTIR spectra reveal spectral features that are nickel-related. These features are observed at 657.7 nm, 722.8 nm, 807.6 nm, 868.8 nm, and 884.7 nm, respectively. In addition, FTIR spectra show N+ at 1332 cm-1. The N+ is thought to result from charge-transfer between Ni and N, leading to formation of the spectral features.

The growth rate of a diamond depends on the convection velocity and temperature gradient. An increased convection velocity results in a higher growth rate. The temperature gradient decreases with increasing diamond volume. The convection velocity increases with the increase in volume. Increasing the convection velocity increases the amount of carbon transported to the seed diamond. A larger volume of the catalyst increases the growth rate of a diamond.

A single-crystal diamond material is a synthetic single crystal with a long abrasion-resistant edge. The aspect ratio of as-synthesised diamond materials is 10 mm or less. This length is equivalent to 7 mm in size. Nonetheless, the aspect ratio may be less or equal to two. In some cases, the aspect ratio is more than 10.

Applications

High-pressure-high-temperature (HPHT) synthesis is a technique that produces single-crystal diamonds with face-to-face parallel growth. These monocrystalline diamonds have long dimensions of at least two millimeters. The process may be pressure-driven, temperature-driven, or both. Some common processes used in HPHT are graphite conversion, phase-balance, and pressure-driven. Regardless of its process, HPHT monocrystalline diamonds are suited for applications requiring both abrasion resistance and a high degree of stability.

The HPHT method allows for lower growth temperature, while reducing the amount of nitrogen-related impurities. This process also reduces the level of hydrogen and silicon-related impurities. The process also yields a lower growth rate, up to 10 mm/h, compared to the standard process that yields 0.3 mm/h. HPHT monocrystalline diamonds are characterized by their low impurity concentration and smooth surface.

The morphology of a single crystal diamond can be either hexagonal or polygonal. The hot morphology is also referred to as octahedral. This type of single crystal diamond is more suitable for single-point dressing applications, because the tip of the crystal is pyramidal. This morphology has a 110 plane, which is more abrasion-resistant than the 100 plane.

Breakable ND grits are microcrystals cropped from larger ND grains. These ultra-hard grits are used to fabricate profiling roll dressers and sintered dressing disks. Once broken, ND grits undergo electroplating and sintered dressing methods. Similarly, broken ND grits are used in cutting tools. This makes HPHT monocrystalline diamonds suitable for cutting tools and ink cartridges.

In the present study, the nanosized diamonds show nickel-related features at 657.7 nm, 722.8 nm, 807.6 nm, and 884.7 nm. This is attributed to a nickel-based solvent catalyst. FTIR spectra of HPHT-produced diamonds exhibit a large N+ peak, and an ultra-narrow band in the UV region.

The aspect ratio of a single crystal diamond seed is at least 30%. Preferably, it’s at least 50%. Other common sizes are 80%, 85%, and 90%. In contrast, a single crystal diamond seed containing fewer than 30% single growth sectors will have fewer extended defects. These defects propagate from regions of high strain in the seed and adjacent to the growth sector boundaries. A single crystal diamond grown on a seed containing this seed is preferably a single-point turning tool with minimal defects.

2mm Yellow HPHT Monocrystalline Diamonds Industrial