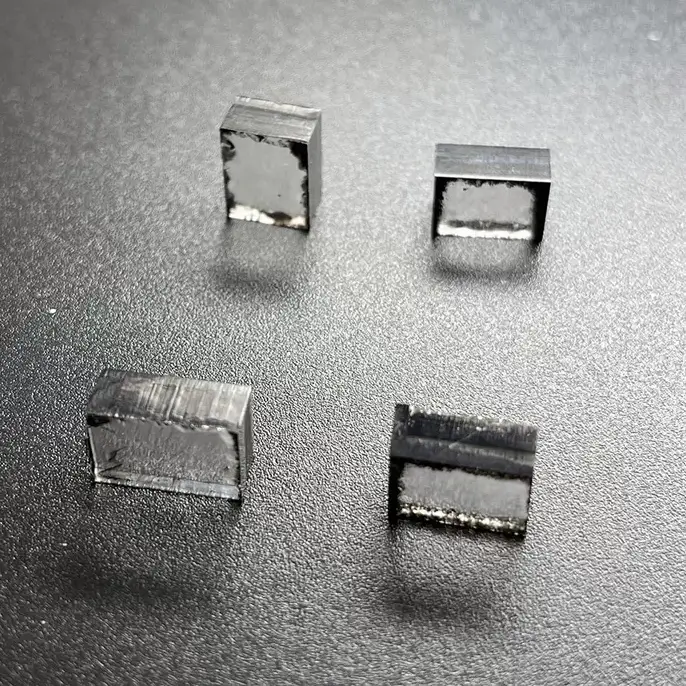

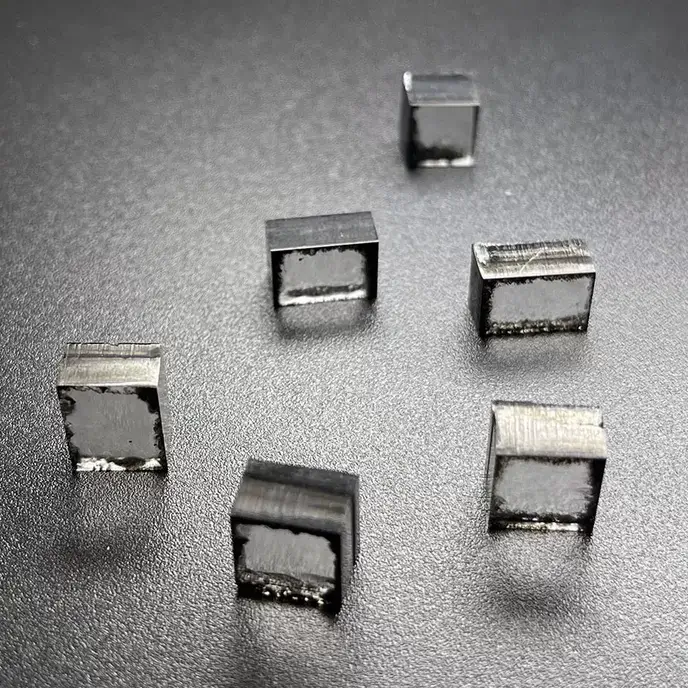

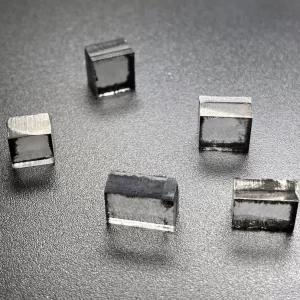

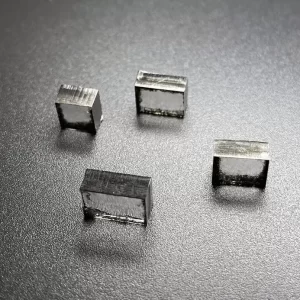

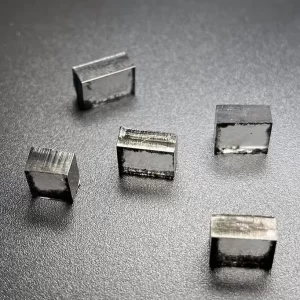

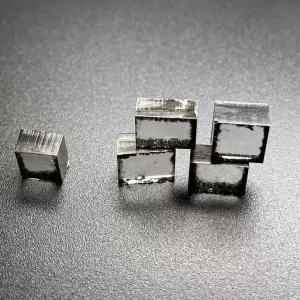

12mm 14mm FG Color Rough CVD Synthetic Diamond

Square Shape 12mm – 14mm FG Color Rough Synthetic Cvd Diamond Made By Cvd Diamond Equipment

CVD Lab Grown Diamonds Description

Lab diamonds, also known as cultured diamonds and synthetic diamonds. Nowadays, there are two main methods to create lab grown diamonds. The two methods are HPHT and CVD methods.

HPHT means High pressure high pressure. It imitates the formation process of natural diamond, puts seeds under great mechanical pressure, and exerts great pressure and high temperature on ready-made carbon. Seeds will quickly turn into diamonds with carbon lattice and grow layer by layer in a few days until they reach the desired carat weight.

Another method called chemical vapor deposition (CVD) is to inject carbon-containing gas into a vacuum chamber and deposit its crystals on synthetic diamond seeds. This method requires lower temperature and lower pressure than the high-pressure high-temperature method. Both methods are currently very popular diamond manufacturing methods. The initial equipment cost of using the chemical vapor precipitation method to manufacture diamonds is lower than that of the high-pressure and high-temperature method, but the diamonds manufactured using this method require subsequent processing to improve the color.

Rough CVD Synthetic Diamond

Before purchasing a rough CVD synthetic diamond, it’s important to understand its properties and characteristics. Here we’ll discuss its properties, cost, and applications. You’ll also discover how to evaluate the material’s quality. Rough CVD synthetic diamond is a highly versatile material that can be used for a variety of purposes. Read on for more information. *What is rough CVD synthetic diamond? *How is it created? *How does it compare to diamonds?

Characteristics

The HPHT method of creating diamonds creates a unique composition containing metallic flux inclusions. Inclusions can be feather-like, irregular, or a variety of other shapes. Diamonds grown by this method are on a single diamond substrate. In a vacuum chamber, hydrogen and methane are activated by a microwave, releasing carbon atoms. The carbon atoms deposit on the diamond substrate layer by layer.

The process of making diamonds using this method is highly complex. The diamond seed crystal is typically a polished synthetic diamond. Hydrogen is pumped through a chamber that contains a diamond seed crystal. A hot filament or microwave generated plasma reacts with the carbon atoms in the seed. The radical species deposit onto the seed diamond, and the chemistry of how the carbon atoms attach to the diamond lattice remains murky.

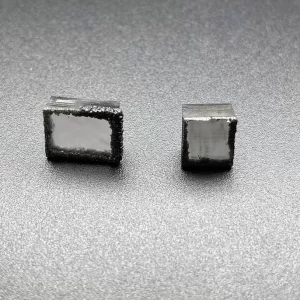

When compared to natural diamonds, CVD diamonds exhibit a lamellar growth structure, while natural diamonds have an irregular, ring-like structure. The results of this study provide the experimental basis for identifying CVD synthetic diamonds. There are many other important differences between natural diamonds and synthetic diamonds, but these two materials are often mistaken for each other. To differentiate the two, one should examine the color grade and refractive index of each sample.

Natural diamonds have characteristic absorption peaks, which are visible when examining the diamond’s surface. CVD synthetic diamonds, on the other hand, always have a high proportion of graphite in their crystal structure, which is particularly common in samples with lower clarity grades. This characteristic also distinguishes CVD diamonds from natural ones. If you want to make a high-quality diamond, this is the way to go.

A systematic study of the CVD synthetic diamonds produced in China will provide a detailed picture of the quality of these gems. China has a large production capacity of high-quality CVD diamonds, which are a key player in the international market. One such study by Zhengshi Technology Co., Ltd. showed that colorless CVD diamonds are largely colorless and had very low levels of nitrogen.

Properties

The synthesis of diamond by CVD is driven primarily by kinetics and not thermodynamics. The diamond is shaped by incorporating a small amount of carbon (typically 5%) and excess hydrogen. During the process, molecular hydrogen is heated to temperatures above 2000K. It is then converted to atomic hydrogen and crystallized into diamond. Various methods are used to generate molecular hydrogen from hydrogen and oxygen.

Although many have claimed to have developed a process to synthesize diamonds, it was not until relatively recently that this method was proven to be feasible. Early pioneers in this field included Henri Moissan, who claimed to have created diamond by heating charcoal at 3,500 degrees Celsius in a carbon crucible. Numerous attempts were made to duplicate the process, but none were scientifically tested. Nonetheless, the synthesis of diamonds by CVD remains an exciting prospect, and a variety of methods is available.

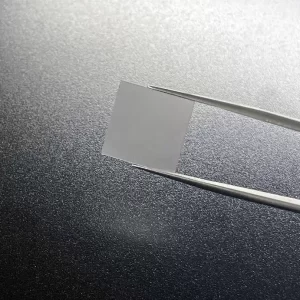

In addition to enhancing the efficiency of the synthesis process, the CVD process also allows for better control of the diamond’s properties. The resultant diamond films are suitable for a wide range of applications including cutting tools, substrates for semiconductors, and windows for optical devices. However, there are a number of drawbacks. Despite the benefits, it is important to consider the entire thermal path and the electrical requirements when designing the synthesis process.

While interstitial point defects are rare in CVD synthetic diamond, they are not impossible. The high atomic density and rigid lattice of CVD diamond means that foreign atoms cannot be easily introduced. However, some small substitutional defects can occur in diamond and act as electron donors and acceptors. In addition, non-carbon atoms may be present in CVD diamond, including P and S.

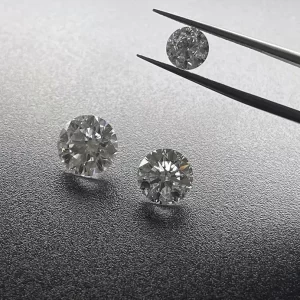

Although both techniques produce diamonds with the same appearance, the two techniques produce different quality materials. Natural diamonds are a form of carbon, while synthetic diamonds are made in labs. While both methods can produce colourless diamonds, the atomic structure of synthetic diamonds is very different. For example, CVD diamonds have a higher carbon content, which means they are more durable and resistant to corrosion. They are also cheaper to produce than diamonds grown by earth mining methods.

Applications

The polycrystalline form of diamond is rough on the surface. Single crystal devices are flat but have a low-grade substrate attached. Most devices undergo mechanical processing. Although the final surface is flat, it does not always offer high spatial resolution, due to the potential for sub-surface damage. Some post-processing etching techniques have been developed and show promise in certain applications. A high-quality contact is critical to a smooth performance.

CVD diamonds are also superior to conventional metals in terms of heat management. CVD diamonds can be crafted in various quality levels and physical properties to match the needs of specific applications. For this reason, the GIA has studied the CVD synthetic process. Its benefits make it a viable alternative to conventional diamonds. The following are some of the many applications of CVD synthetics. All of these applications have their own pros and cons.

The strong lattice of diamond contributes to its stiffness and radiation hardness in detectors. The strength of diamond helps it form robust optical windows. Diamond’s high transparency over a broad wavelength range is both technically and functionally fascinating. For example, diamond’s millimetre-thickness made it useful for applications requiring long wavelengths, but control over absorption in single crystal diamond opens up a number of applications with visible light.

As far as the growth mechanism of CVD synthetic diamond is concerned, the process of synthesis is still being investigated. However, it has been shown that the chemical vapour deposition (CVD) process is capable of producing areas of 4 x 4 mm2. It has also been reported that CVD diamonds can be produced in a metastable regime. Only time will tell if CVD diamonds will reach the size of their HPHT cousins.

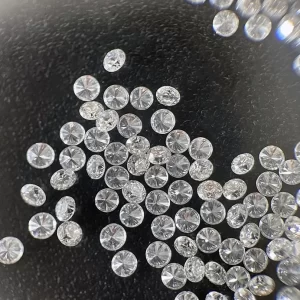

Although most CVD synthetics are round, there are also fancy shapes available, including emerald cut and rectangle. Some manufacturers also prefer to facet their material in the same way as round brilliants so that the fancy shapes retain some of the original crystal’s weight. If a synthetic diamond has been produced using this process, it is most likely to have excellent quality. This is the only way to ensure its durability and quality.

Cost

Natural diamond has been used in microwave and laser diode devices for over a century. However, the availability of natural diamond plates has limited its market penetration. Polycrystalline CVD diamond has similar thermal properties as natural diamond, and it is available from several sources. It is grown in large wafers, which allows it to be used in arrays that are several centimeters in diameter. This type of diamond also costs much less than its natural counterpart.

While natural diamond prices are higher, rough CVD synthetic diamonds are relatively inexpensive. The CVD process, which creates the diamond in a vacuum chamber, involves introducing gas molecules into the diamond-forming process. Microwaves are used to activate and break down the gas molecules. Once the hydrogen reacts with the graphite, the resulting diamond is created. Compared to natural diamond, CVD diamonds are cheaper and are available for multiple purposes.

Because diamond is one of the hardest and most valuable gemstones, lab-created ones are a cheaper alternative to real diamonds. Previously, lab-created diamonds were too expensive to compete with natural diamonds in the jewelry market. However, technological advancements and the growing consumer demand for less-expensive alternatives has lowered prices. A recent survey revealed that the prices of rough CVD synthetic diamonds have dropped by more than 20%.

However, the lack of a standard measurement method makes it difficult to accurately predict the strength of synthetic diamonds. The earliest tests used in the United States were performed with small samples, which is inconvenient for many manufacturers. This method is also less expensive than CVD synthetic diamond. However, it has its limitations. It is not consistent because samples are not uniformly prepared, making the results hard to reproduce. A better method would be to use a standard diamond grading process to ensure consistency of results.

The price of a CVD synthetic diamond depends on a variety of parameters. While natural diamonds are more expensive than synthetic ones, a laboratory-grown diamond is priced similarly to natural diamonds of similar quality. The only difference between natural and lab-grown diamonds is the production process. The lab-grown diamonds will be priced by production costs plus a profit margin. Similarly, Chinese producers are increasing their production of cheap manufactured diamonds.

12mm 14mm FG Color Rough CVD Synthetic Diamond