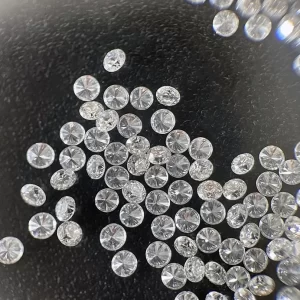

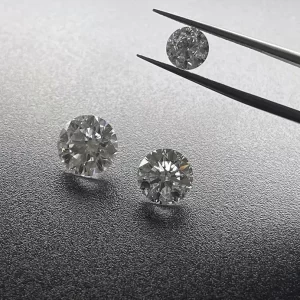

1.8mm To 2.0mm Yellow HPHT Monocrystalline Diamonds SI To I Clarity

1.8-2.0mm Yellow HPHT Monocrystalline Diamonds For Diamond Cutting Tools Making

HPHT Monocrystalline Diamonds Description

Lab diamonds are real diamonds. Carbon is the main element of natural and laboratory-grown diamonds. The chemical and physical properties of synthetic diamonds are same as natural diamonds in terms of hardness, thermal conductivity, and strength.

High temperature and high pressure (HPHT) and chemical vapor deposition (CVD) are the two most commonly used growth methods in synthetic diamonds industrial. High temperature and high pressure exert intense heat (about 1500 degrees Celsius, or 2700 degrees Fahrenheit) and pressure (1.5 million pounds per square inch) on the diamond seed and the carbon atoms surrounding it. Chemical vapor deposition, on the other hand, uses less heat and pressure, but introduces a mixture of chemical gases, which decomposes and hardens into crystalline carbon atoms.

Diamond is divided into two types: type I and type II, which is mainly based on whether it contains N element: type I contains N element; type II contains N element; Type II does not contain. And the blue diamond is type 2B, semiconductor.

Due to its excellent optical, thermal and electrical properties, type II diamond plays an irreplaceable role in many fields, such as optics, electronics, atomic energy, space technology, high energy physics and medicine, especially in the field of high-tech and cutting-edge technology. For example: using its thermal conductivity to make super heat sink materials; Making use of its light transmittance, we can make various window materials, such as high power laser window and infrared detector filter; Using its photoconductivity, it can be used in nuclear industry, automation technology and medicine; It can be used as high function semiconductor material.

Diamond Size: 1.8mm 2mm

Application: Diamond tools making

Yellow HPHT Monocrystalline Diamonds

In commercial diamond growth, HPHT processes use the Fe-Ni-Ti-C system. HPHT monocrystalline diamonds contain high levels of nitrogen. Unlike natural diamonds, which grow in an Fe-Ni-C system, HPHT-treated ones exhibit unusual platelet peaks and strong emission of H3 centres. These diamonds are highly desirable for use in jewelry and scientific research. But what is the real nature of HPHT?

High content of nitrogen in HPHT monocrystalline diamonds

Yellow HPHT monocrystalline diamonds may have high levels of nitrogen in their structure. Nitrogen is a major component of diamonds. It is believed to cause the initial color of diamonds, which is brown. During the HPHT process, the nitrogen centers in the diamond are broken or rearranged. The resulting color may be yellow or blue-green. During this process, diamonds may reach a stable point where the nitrogen content in the stone drops.

The content of nitrogen in yellow HPHT monocrystalline diamagnetic diamonds is also elevated due to the presence of metallic Ti. Metallic Ti has a high reactivity towards oxygen and is important in the crystallization of low-nitrogen diamonds. Studies have shown that the high P-T of metallic Ti is responsible for the formation of low-nitrogen diamonds. In addition, Ti is an important component of the Fe-Ni-C mixture and plays a major role in the formation of low-nitrogen diamonds.

HPHT process is widely used for synthetic diamond growth. It involves a number of steps: the steel cap, graphite heater, sheet graphite, alloy catalyst, seed crystal, and ZrO2-MgO pillar. In HPHT, nitrogen is captured in the crystal growth by dissociation in the transition metals of the Fe group. The nitrogen used in HPHT process is usually obtained from air.

The D19 EPR spectrum can be compared with that of milled Ib HPHT diamonds. The mean size of Ib HPHT diamonds is 18 to 390 nm. The D19 EPR spectrum is devoid of P1 HFS signatures while it is present in intermediate-sized samples with 85-130 nm. This indicates that there is an increased surface area of polycrystals.

Another reason for the high nitrogen content in yellow HPHT monocrystalline diamonds is the presence of NV centres and multivacancies in the monocrystalline crystals. Both the NV centres are required for cathodolumescence integrated correlation electron-light microscopy (CLICEM) techniques. The NV0 and NV centres in yellow HPHT monocrystalline diamonds are largely absent in type IIb HPHT nanodiamonds.

Similarly, the nitrogen content of Type IaA and Type IbHPHT monocrystalline diamonds may be less than 130 ppm. While diamonds with higher nitrogen content tend to have more red and purple colors, those with lower levels are not. However, it is possible to identify diamonds with a high nitrogen content using a few methods. However, these tests should not be relied on solely on speculative data.

The high content of nitrogen in yellow HPHT monocrystalline diamonds may be attributed to the annealing process. Diamonds are annealed under conditions known to cause color changes. For instance, when a diamond is exposed to a laser beam, it is bombarded with electrons. This process changes the diamond’s structure, increasing the excitation state. However, the change in color is believed to be unstable.

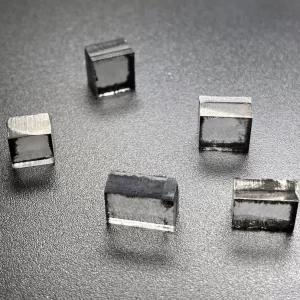

Colorless diamonds are grown in Fe-Ni-Ti-C system

The growth of colorless HPHT monocrystalline diamonds in a Fe-Ni-Ti-C (Fe-Ni-Ti-C) system requires a nitrogen getter (Ti) and a decomposer (Cu) at high concentrations. The two components are required because Ti is a nitrogen getter and Cu is a decomposer. The resulting diamond crystals are colorless or yellow.

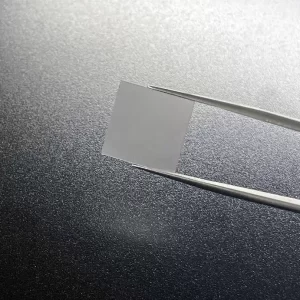

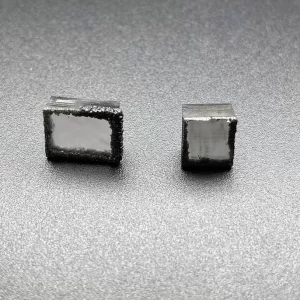

The growth process requires an alloy catalyst and a steel cap. It also includes a graphite heater, seed crystal, and a ZrO2-MgO pillar. The diamonds formed by HPHT have a small amount of preferred crystallographic orientation. If the growth conditions are adjusted correctly, a single crystalline diamond plate of 92 mm can be grown.

The growth of HPHT and CVD synthetic diamonds has increased tremendously. Now, there are several companies producing single-crystal HPHT diamonds up to 4 cts. Although chemically identical to natural diamonds, the growth process is very different from that of natural diamonds. For example, HPHT diamonds are formed from graphite, not from natural diamonds.

HPHT and irradiation processes result in the formation of diamonds with single or near-colorless nitrogen. However, these processes also lead to the formation of yellow diamonds that contain a trace amount of nitrogen. Hence, the synthetic diamonds are difficult to differentiate using standard gemological methods. These methods may also be less reliable if applied on low-nitrogen HPHT diamonds.

The low-pressure growth principle has its limitations. Diamond growth on substrates has the disadvantage of removing the sp2 carbon during the process. It also has some drawbacks owing to the substrate geometry and reproducibility. The process parameters used in HPHT monocrystalline diamond growth in Fe-Ni-Ti-C system have been summarized in Table 1.

The growth of HPHT diamonds depends on many factors. These include the substrate’s chemical composition, surface roughness, and the presence of particles that are left over after surface preparation. Generally, rough surfaces provide more active spots for nucleation of diamond. Moreover, diamond is commonly used in seeding the substrates or seeding with nano-diamonds.

The first-order spectrum of HPHT monocrystalline diamonds grown in Fe-Ni-Ti.C system is characterized by a sharp diamond line near 1332 cm-1. The D and G bands are much more prominent with decreasing grain size, and they overlap the diamond line. If grain size of the diamond is 50 nm or less, the Raman spectrum will reveal a black or red line.

Moreover, this process can also distinguish colorless diamonds from colored ones. The process of screening a diamond in the Fe-Ni-Ti-C system can be highly automated. Diamond screening is a key part of gem-quality control, and it can help identify synthetic diamonds from natural ones. There are many methods of screening a diamond, some of which are designed for small parcels.

IVB-elements are used in commercial HPHT diamond growth

Using IVB-elements in diamond growth techniques has numerous advantages. For example, it enables whole diamonds and individual layers to be created with blue coloration. The amount of boron in the precursor gas can be controlled to yield a concentration of 0.05 ppma to 3,000 ppma in the diamond. In addition, increasing the level of boron doping increases the optical absorption coefficient of the diamond.

The high thermal conductivity of single crystal diamonds is important for various industrial applications. Under certain conditions, these diamonds have a thermal conductivity of 2200 W/mK and a high quality. These characteristics make them suitable for wire dies, optical windows, and tools. The high thermal conductivity of these diamonds also allows them to be used as heat spreaders and other products.

Statistical analyses of HPHT synthetics are also useful to distinguish between natural and synthetic diamonds. For example, HPHT synthetic diamonds display distinctive fluorescence patterns and lack strain when viewed with crossed polarizers. Furthermore, the color of HPHT synthetic diamonds has undergone noticeable changes in the past decades. In the early years, orange-yellow samples constituted the majority of HPHT synthetic diamonds. Today, blue samples are more common.

IVB-elements are also a valuable component of IVB-elements. The process used in commercial HPHT diamond growth is a simple, fast, and reliable method for the production of high quality diamonds. Unlike many other methods, IVB-elements can be dissolved in water and are also highly stable in high pressure conditions. After the growth is completed, the film is cooled to room temperature and the reactor is filled with room air to atmospheric pressure.

Colorless synthetics are the most desirable. Although natural diamonds often display interference colors, HPHT colored synthetics have uniform coloration. Unlike natural diamonds, HPHT-grown diamonds grow under uniform pressure. This means that they do not exhibit strain patterns. This is an important feature for HPHT colored diamonds. This characteristic helps to differentiate natural diamonds from HPHT-grown ones.

The thermal conductivity of natural and synthetic diamonds has been studied. While both are known to have high thermal conductivity, natural diamonds exhibit a lower number of isotopes than synthetic ones. Thus, in the case of diamonds, using the method of isotope enrichment will help improve the thermal conductivity of these two materials. This feature can be extremely useful for high power devices, such as communications lasers and semiconductors.

The invention also relates to a method for forming synthetic diamonds. The method includes growing a monocrystalline diamond and removing impurities from the growing chamber. Impurity-doped layers, doped diamonds, and doped monocrystalline diamonds are also possible. Additionally, the invention relates to the method of producing synthetic diamonds, as well as the methods used in performing this method.

1.8mm To 2.0mm Yellow HPHT Monocrystalline Diamonds SI To I Clarity