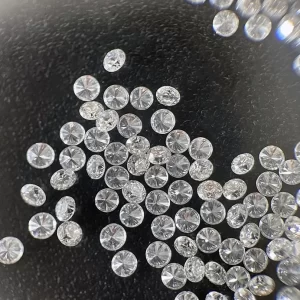

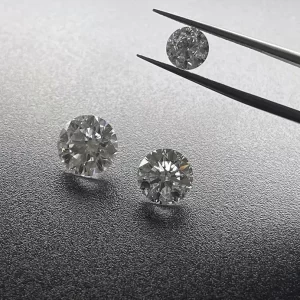

1.4mm 1.6mm HPHT Monocrystalline Diamonds Low Grade

HPHT Monocrystalline Diamonds Description

Lab diamonds are real diamonds. Carbon is the main element of natural and laboratory-grown diamonds. The chemical and physical properties of synthetic diamonds are same as natural diamonds in terms of hardness, thermal conductivity, and strength.

High temperature and high pressure (HPHT) and chemical vapor deposition (CVD) are the two most commonly used growth methods in synthetic diamonds industrial. The traditional diamond manufacturing method is called the high pressure high temperature (HPHT) method. It uses a device to simulate the high pressure and high temperature conditions of natural diamonds when it is formed underground, and uses carbon materials in the device to produce synthetic diamonds. A relatively new method called chemical vapor deposition (CVD) is to inject carbon-containing gas into a vacuum chamber and deposit its crystals on synthetic diamond seeds. This method requires lower temperature and lower pressure than the high-pressure high-temperature method. Both methods are currently very popular diamond manufacturing methods.

Lab diamond is not only of high commercial value, but also widely used in industry. As the hardest material known to human beings, with the development of science and technology, HPHT Monocrystalline Diamonds is widely used in cermet materials, oil drilling, construction engineering, mechanical processing, instrumentation, electronic industry, aerospace and other fields. The size of diamond is larger and larger, and the purity of diamond is also more and more pure, especially in jewelry, there is a lot of room for development. These synthetic HPHT monocrystalline diamonds have similar properties to natural diamonds and can be produced at a lower cost.

Diamond Size: 1.4-1.6mm

Mesh Size: 8/12

HPHT Monocrystalline Diamonds – Dimensions and Shape

One way to determine if an HPHT monocrystalline diamond is truly synthetic is to examine its dimensions and shape. To do this, you should first understand how diamonds are created. Dimensions are the dimensions that are present in a single crystal of diamond. Size is another dimension that is included in the grading system. In terms of cost, a single HPHT monocrystalline diamond can cost anywhere from a few hundred to several hundred thousand dollars.

Size

HPHT-synthesised diamonds can be larger than natural diamonds, and their morphology is tuned to the exact specifications required for various applications. This technology has numerous advantages, including improved morphology and improved wear resistance. Diamonds are also extremely hard, making them ideal for applications such as laser machining, optical components, and X-ray windows. However, the process can produce a variety of problems, including crystalline defects.

Ideally, a single crystal diamond seed has at least 30 percent, 50%, 80%, 85%, and 90% single-growth sectors. Single-crystal diamonds that have this crystalline habit have fewer extended defects, which propagate from regions of high strain in the seed and adjacent to growth sector boundaries. A single-crystal diamond should have fewer defects, such as inclusions, than a natural diamond.

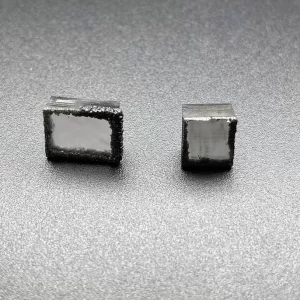

HPHT-synthesised diamonds are a unique kind of diamonds. The process of creating single-crystal diamonds consists of pressing seeds into a seed pad. The seeds have a face facing the surface of the seed pad. The seed pad is made of a material called a substrate. A suitable substrate may be a ceramic material, a salt, or an alkali metal halide.

One of the benefits of HPHT-synthesised diamonds is their large size. HPHT process yields a single-crystal diamond that has an aspect ratio of at least 1. The temperature of the HPHT-synthesised diamond is typically between 1280 and 1390 degrees Celsius. The HPHT method is also known as the temperature gradient process. Listed below are a few of its advantages. Once you learn more about HPHT-synthesised diamonds, you will soon see why this method is the most efficient and successful.

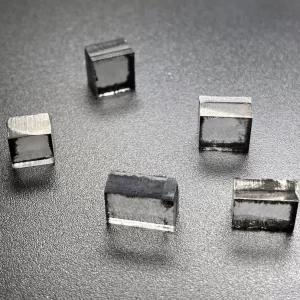

Shape

The shape of HPHT Monocrystalline Diamonds can be controlled by varying the seed surface morphology. The external morphology of the single crystal diamond of the present invention has an octahedral shape. Approximately ten percent of the surface area of the as-grown stone is composed of planes of the 100 and 111 types and the remaining area is made up of the 110, 113, and 115 types.

The HPHT method of single crystal diamond was first reported in the patent WO2008/107860. The method is reported to produce synthetic single crystal diamond materials with reduced metallic inclusion content. The current patent sought to improve the method of generating high-quality single-crystal diamond materials with a long edge length and crystallographic orientation properties. It does this with a small seed and relatively high growth rates. However, in order to realize the full potential of the HPHT process, a small number of new patents had been filed.

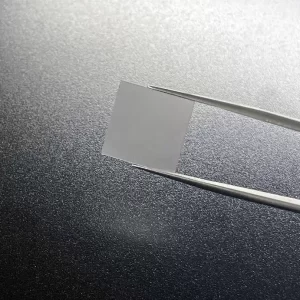

A single crystal diamond seed preferably has two opposed edges of less than 10deg, thirty or fifty degrees. At x10 magnification, a single crystal diamond seed’s side facets are preferably between 0 and five degrees. The surface roughness Ra of single crystal diamond seeds is preferably less than 80. Optical microscope images of a single crystal diamond seed are preferably within a radius of two mm.

HPHT method is a well-known synthetic process for single crystal diamonds. The process produces a single-crystal diamond with an aspect ratio of at least one. The diamonds are formed on a substrate made of any material commonly used in HPHT. Examples of suitable substrates are alkali metal halides, ceramic materials, and salts. Once the diamond seeds are in place, they are pressed into a seed pad.

CMI

HPHT-synthesised diamond crystals are capable of displaying unique features. The incorporation of metal atoms from a catalyst metal into the diamond lattice can be identified using photoluminescence spectroscopy. These characteristics enable diamond crystals grown by HPHT to be particularly suited for specific applications. Here are some examples of the features of HPHT-synthesised diamond crystals.

A natural octahedral stone has eight surfaces, each of form 111. Likewise, a skilled artisan will refer to two and three-point planes as 4-point directions. This practice is especially common in diamond tool making. The maximum dimension, or long dimension, of a single crystal diamond, is referred to as its facet. Its facet ratio will be proportional to the size of the crystal.

A hard mask layer consisting of seven um SiO2 and 200 nm Al is formed on the diamond surface. This layer prevents cracking of the thick SiO2 hard mask. In addition, the two-step photolithography procedure is effective in removing edge beads, enabling a high-fidelity photolithography process. In addition, a sacrificial Al layer is deposited between the diamond and handling wafer. The fabricated components can then be removed without any difficulties.

The CMI HPHT process is designed to create a single-crystal diamond with an external morphology predominantly octahedral. The surface of the as-grown stone comprises at least 10% of 111-type planes, 15% of 100-type planes, and the remaining portion consists of 110-, 113-, and 115-type planes. The as-grown stone is a composite of these two types of planes.

Dimension

Dimension of HPHT monocrystalline diamonds refers to the shape of the single crystal. These diamonds have the dimensions and shape suitable for many applications. They also minimize the need for post-synthesis cutting processes, which lead to considerable waste of diamond material. However, the dimension of HPHT monocrystalline diamonds is not as well defined as that of the polycrystalline diamond. This is because the size of the single crystal diamond varies according to the process used to synthesize it.

The cuboctahedron morphology of HPHT diamonds is one of its most attractive characteristics. The diamond’s surface structure and shape can be tuned using different doping solutions such as Boron and Nitrogen. The concentration of these elements can vary from 0.01% to 10 ppm. HPHT monocrystalline diamonds can be either square or rectangular, but no one is sure of which form will give it the most beautiful appearance.

In order to produce a high-quality synthetic diamond, HPHT technology is used. The synthesis process produces diamond particles with high thermal conductivity and high wear resistance. The raw synthetic stone is then sorted into different grades, reflecting a flawless crystal as well as one with some internal inclusions. High-precision parts are often produced by using monocrystalline diamond tools. The surface finish can be as low as 0.025 micron.

In the process of HPHT monocrystalline diamonds, the present inventors have discovered a high-quality single-crystal diamond with a large aspect ratio. The resulting diamond is also highly wear-resistant with a long edge and reduced metallic inclusion content. With these properties, the diamond is suited for use in many tool applications. The dimension of HPHT monocrystalline diamonds can be manipulated for a wide range of purposes.

Applications

Novel HPHT monocrystalline diamonds are a key ingredient in nanotechnology and a rapidly growing market. Their unique properties allow them to be used in various applications ranging from medical devices to electronics. These diamonds are the only natural materials with the ability to read and initialise spin qubits at room temperature. They will allow researchers to perform high-resolution magnetic sensing and safe navigation in GPS-denied environments. The diamonds also have an impressive spectral power, with peak emission peaks of up to 1332 cm-1.

The process produces a single crystal diamond with a face parallel to the seed crystal growth surface. The longest dimension of a single diamond is 2 mm. The process is driven by temperature and pressure and may be a phase-balance or graphite conversion process. In either case, the HPHT process is performed at a temperature of 1280°C to 1390°C. The process is highly scalable and can be scaled up to multiple microns in size.

High-pressure, high-temperature synthesis of single-crystal diamond materials typically begins with a seed pad. The seeds are then pressed into a substrate, which is made of a common material for HPHT synthesis. Materials suitable for the substrate include ceramic materials and salts. This process produces monocrystalline diamond material with high strength and wear resistance, and long edges. HPHT monocrystalline diamonds may be used in a variety of applications including the manufacture of jewelry.

The MPCVD method can produce high-quality single crystals. The growth rate is typically 50 to 150 mm/h and varies between low and high-methane concentrations. The MPCVD method can also be used to expand anvils, increase growth rate, and compress large samples at ultrahigh pressures. While HPHT is a relatively new technology, it has many advantages and is currently gaining acceptance in the industry.